CNC Software Market Synopsis

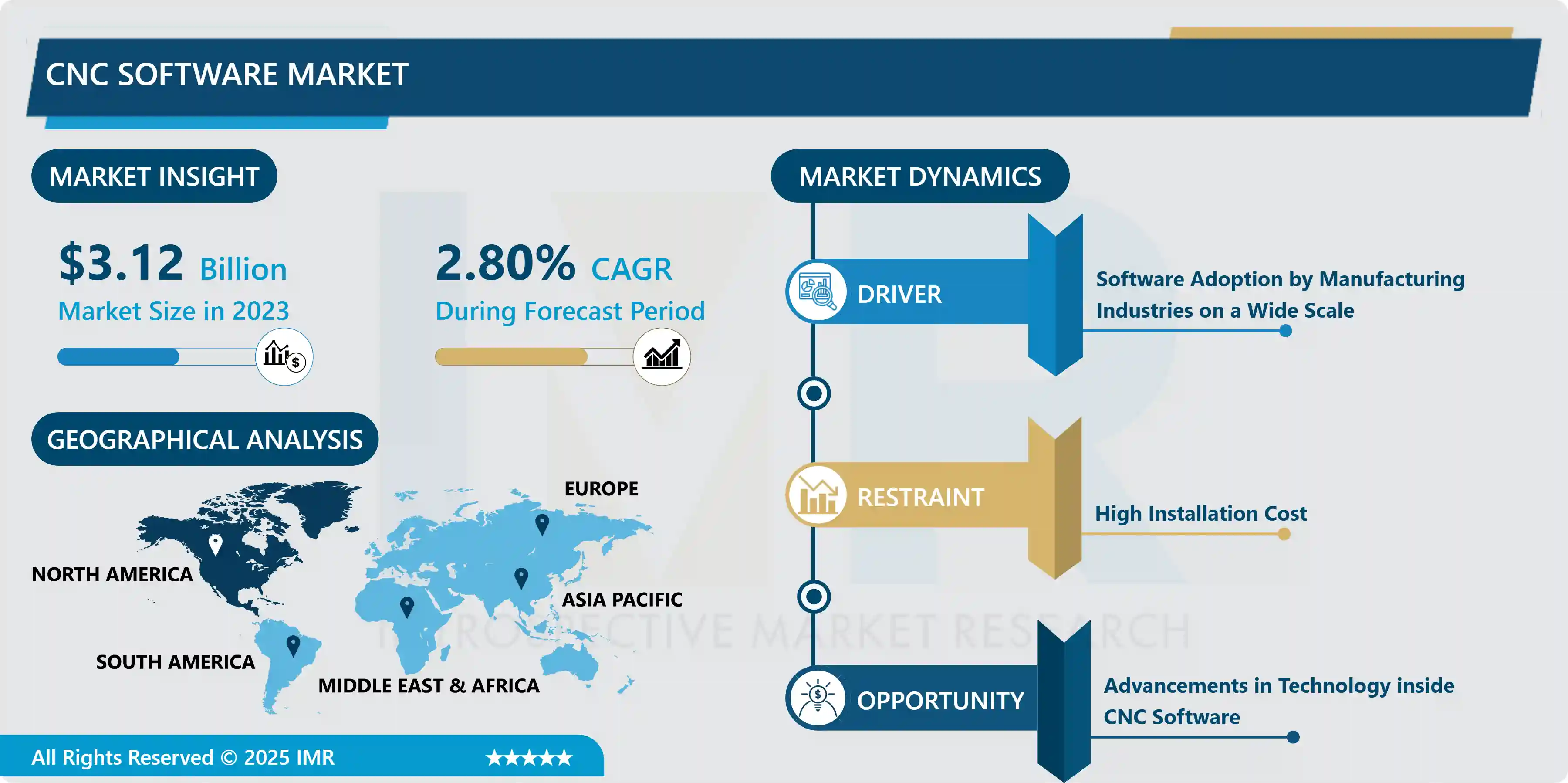

CNC Software Market Size is Valued at USD 3.12 Billion in 2023 and is Projected to Reach USD 3.90 Billion by 2032, Growing at a CAGR of 2.80% From 2024-2032.

CNC, which is abbreviation for Computer Numerical Control software, is one pivotal element indispensable in the automated machining since it delivers commands to machines to execute precise movements based on digital instructions. This process carries numerous functions, including transformation of the blueprint into commands for the cutting tool's movement and other machinery. Offline CNC software is among the enablers of key industries such as manufacturing where the machines produce many complex and precise parts with efficiency and accuracy.

The CNC software market is primarily governed by the growing proliferation of computer numeric control (CNC) machines in manufacturing, automotive, aerospace, and healthcare rather than the implementation of CNC machines themselves in the industries. These tools are used to manufacture parts with a precision that is facilitated to the machines by sophisticated software that controls the machine`s operations with a high level of accuracy.

Automation and efficiency are not the essential drivers of the future of work, but they remain vital considerations in manufacturing process development. CNC software makes it feasible for manufacturers to eliminate human errors, automate its tasks, and consequently produce better results. Furthermore, there are smart ones and that is a next generation of industry. Through no 0 initiatives, now leading the demand for CNC software since it is the foundation for building networks between machines and systems in the exchange of information for integration.

Apart from that, substantial improvements to the CAD/CAM software, which is often embedded to the CNC software, matter to market expansion. CAD/CAM is also the solvent used for the work to be realized by CNC machine that is then programmed to operate the machines.

CNC Software Market Trend Analysis

Cybersecurity in CNC Software, Safeguarding Machines and Data

- The Software (Computerized Numerical Control) market is currently overcoming a variety of significant trends. Cloud-based CNC software solutions are revolutionary in a way that increasingly remote access, real-time monitoring, and data analytics are being required, thus, being the reason for the high demands for CNC software solutions. Particularly in the sectors that production methods affect productivity such as vehicle, airplane, and electronic devices manufacturing industries, this habit prevails to the utmost.

- Moreover, the major software suites are almost converged into one that offers more than the programing functions by incorporating production monitoring, simulation, as well as optimization. This approach marks the fulfillment where production can be increased all over and the various processes can be coordinated.

- The increase in AI (Artificial Intelligence) solutions and machine learning that happens in the CNC software too is one of the trends. These technologies are widely employed to increase productivity of the entire machining process; automate toolpath trajectory optimization; and enlarge predictable maintenance capabilities.

- Ultimately, as more CNCs are digitally connected, cybersecurity in the CNC software also gains a greater share of the limelight. As a defense against any systems and data fraud, manufacturers are putting forward software solutions with high-quality security, and so the manufacturers are aware of the threats posed by the cyberattacks.

Seizing Opportunities, Dynamics Shaping the CNC Software Market

- Various factors are opening the pathway for the market of CNC software to develop as a whole. While a growing number of manufacturers demand accuracy and automation in manufacturing processes in several industries, the large-scale use of robots in factories provides a great opportunity. While the software is the driver of the increasing popularity of the CNC technology, it is done through its contribution to the productivity, high precision and efficiency of the industrial process.

- In fact, CNC software suppliers are leveraging the growing trend towards smart manufacturing and Industrial Revolution 4, therefore. 0. These technologies have to enable system and intersystem links that would be possible only through state-of-the-art software solutions.

- Automobile and aerospace industries, i.e. one of the most important fields of production, especially in the case of the rapidly developing markets, are also important engines of the CNC software market growth. For potential firms in production activities, the aim is to achieve the best quality and precision. Such a task impossible without good software solutions.

- Additionally, CAM software developers are expanding their scope with the explosion of additive manufacturing technology, which is popularly called 3D printing. Educating cnc machining software is a factor for these non-conventional manufacturing methods, which we use them as post-processing the above mentioned additive manufacturing technologies frequently.

CNC Software Market Segment Analysis:

CNC Software Market is segmented on the basis of product, application.

By Product, Cam Software segment is expected to dominate the market during the forecast period

- Three essential products in the field of CNC software are crucial at different points during the manufacturing process: In general CAM software, commonly known by the abbreviation CAD (computer-aided design) is a key technology in moving from CAD models to machine code which is used in controlling of CNC machines. It gives manufacturing shops higher efficiencies, controls cutting operations, and mutually defines the toolpaths. CAM software is used in CNC machining due to multitasking, simulation and multiaccess motion control capabilities features.

- CAD (Computer-Aided Design) software is particularly helpful in generating advanced 2D or 3D patterns for parts and parts. They, as machining reference systems, operate smoothly with CAM software, creating toolpaths. In contrast to the earlier methods whose accuracy and speed were poor, design teams now prefer to use CAD software, which facilitates more concerted and accurate collaboration. CAE software’s enable engineers to modelling and checking the performance of the product under different situations using the strength provided by CAE. It increases the agility of the process by reducing the volume of physical prototypes, and enhancing capabilities such as behaviour prediction, and design optimization. To ensure a high product quality, dependability and affordability of the computer is CAE software vital.

- Every one of these software products are imperative to CNC manufacturing process and helps manufacturing practitioners to improve productivity, accuracy, and creativity in the modern industry.

By Application, Drills segment held the largest share in 2023

- Three essential products in the field of CNC software are crucial at different points during the manufacturing process: Generally, CAM is a software which can easily be abbreviated as computer-aided manufacturing software. It is a major tool in the tool chain to facilitate the conversion of CAD model to G code which is the proprietary language used by the CNC machinery. It elevates the rate of manufacturing, guides the machining procedures, decrease setting times and maintain the accuracy level.

- What these programs entail is anything from post-processing and simulation to multi-axis machining, making CAM software necessary for intricate engineering tasks. One of the strongest utensils of the Computer-Aided Design, or CAD, is that it multi-purpose to produce precise 2D or 3D models of parts or completely finished goods. These models not only serve as an alternative to manufacturing as they are connected with cam software and produce toolpaths.

- In this case, teams of designers could communicate with each other much more reliably and accurately if they have CAD software. The use of Computer-Aided Engineering (CAE) software by the engineers allows them can foresee how their product will work with different variables. Simulation engineers use graphic software which substantially reduces the demand on creating physical prototypes and predicts the behavior and optimize the design result. As opposed to real-life situations, where product performance may be compromised, CAE software guarantees reliable and cost-effective results.

- Actually, every software subcategory plays its own part in CNC production process and ensures the high production rate and precision as well as high level of creativity of contemporary manufacturers.

CNC Software Market Regional Insights:

North America is Expected to Dominate the Market Over the Forecast period

- Technological Developments: North America is famous for its state-of-the-art technology and has exemplified smart industrial techniques that are becoming the adoptive cure of the day. The essence of CNC software to boost the production capacity is constituted by the creative driven forces.

- industrial Sector: Due to the fact that region has a big industrial sector concentrated in such industries as electronics, automotive, and aerospace that represents the heterogeneity of the region highly it is demanded CNC software is that software we need. CNC software supplies the machining solutions which have a high precision level and are more than the sectors demand.

- Adoption of Automation: The thirst for having higher efficiency and less expenditure has made the room for automation a key trend in the North American industry. The worth of CNC software has gained a lot of admiration among users because it is the one that is critical in automating manufacturing processes.

- Prioritize Productivity and Quality: American industries understand the importance of both consumption patterns and waste disposal. These priorities are based on multitude of advantages that companies can enjoy through the use of CNC software, such as accuracy, reliability and superb efficiency.

- Competitive Landscape: There are many software providers in nearby theseces, which ensure product development and race. Since competitive environment is intensified between developers of CNC software, each of them strives to create more efficient, effective and innovative features to make their products more appealing to customers.

- Regulatory Environment: Periodic and sticky quality and safety standards are usually a requirement from the largely regulated community in North America, it is especially highlighted in the sectors like aerospace and healthcare. Standard or governmental regulations are a aid for manufacturers due to CNC software.

- Market Dynamics: With a no of factors such as industry trends, technological breakthroughs, and economic state influencing the CNC software business in the North America continent. The market of critical product sees its shape and growth being driven by these factors.

Active Key Players in the CNC Software Market

- WorkNC (France)

- UG (United States)

- Cimatron (Israel)

- Powermill (United Kingdom)

- ProE (United States)

- 3DS (United States)

- Cimatron Group (Israel)

- KND (China)

- GSK CNC EQUIPMENT (China)

- Others

|

Global CNC Software Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 3.12 Bn. |

|

Forecast Period 2024-32 CAGR: |

2.80% |

Market Size in 2032: |

USD 3.90 Bn. |

|

Segments Covered: |

By Product |

|

|

|

By Application |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

Chapter 1: Introduction

1.1 Scope and Coverage

Chapter 2:Executive Summary

Chapter 3: Market Landscape

3.1 Market Dynamics

3.1.1 Drivers

3.1.2 Restraints

3.1.3 Opportunities

3.1.4 Challenges

3.2 Market Trend Analysis

3.3 PESTLE Analysis

3.4 Porter's Five Forces Analysis

3.5 Industry Value Chain Analysis

3.6 Ecosystem

3.7 Regulatory Landscape

3.8 Price Trend Analysis

3.9 Patent Analysis

3.10 Technology Evolution

3.11 Investment Pockets

3.12 Import-Export Analysis

Chapter 4: CNC Software Market by Product (2018-2032)

4.1 CNC Software Market Snapshot and Growth Engine

4.2 Market Overview

4.3 CAM Software

4.3.1 Introduction and Market Overview

4.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

4.3.3 Key Market Trends, Growth Factors, and Opportunities

4.3.4 Geographic Segmentation Analysis

4.4 CAD Software

4.5 CAE Software

Chapter 5: CNC Software Market by Application (2018-2032)

5.1 CNC Software Market Snapshot and Growth Engine

5.2 Market Overview

5.3 Drills

5.3.1 Introduction and Market Overview

5.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

5.3.3 Key Market Trends, Growth Factors, and Opportunities

5.3.4 Geographic Segmentation Analysis

5.4 Boring Tools

5.5 Lathes

5.6 Other

Chapter 6: Company Profiles and Competitive Analysis

6.1 Competitive Landscape

6.1.1 Competitive Benchmarking

6.1.2 CNC Software Market Share by Manufacturer (2024)

6.1.3 Industry BCG Matrix

6.1.4 Heat Map Analysis

6.1.5 Mergers and Acquisitions

6.2 ADVANCED MICRO DEVICES (US)

6.2.1 Company Overview

6.2.2 Key Executives

6.2.3 Company Snapshot

6.2.4 Role of the Company in the Market

6.2.5 Sustainability and Social Responsibility

6.2.6 Operating Business Segments

6.2.7 Product Portfolio

6.2.8 Business Performance

6.2.9 Key Strategic Moves and Recent Developments

6.2.10 SWOT Analysis

6.3 ARM LTD (UK)

6.4 CLARIFAI (US)

6.5 ENTILIC(US)

6.6 GOOGLE (US)

6.7 HYPERVERGE(US)

6.8 IBM (US)

6.9 INTEL (US)

6.10 MICROSOFT (US)

6.11 NVIDIA (US)

Chapter 7: Global CNC Software Market By Region

7.1 Overview

7.2. North America CNC Software Market

7.2.1 Key Market Trends, Growth Factors and Opportunities

7.2.2 Top Key Companies

7.2.3 Historic and Forecasted Market Size by Segments

7.2.4 Historic and Forecasted Market Size by Product

7.2.4.1 CAM Software

7.2.4.2 CAD Software

7.2.4.3 CAE Software

7.2.5 Historic and Forecasted Market Size by Application

7.2.5.1 Drills

7.2.5.2 Boring Tools

7.2.5.3 Lathes

7.2.5.4 Other

7.2.6 Historic and Forecast Market Size by Country

7.2.6.1 US

7.2.6.2 Canada

7.2.6.3 Mexico

7.3. Eastern Europe CNC Software Market

7.3.1 Key Market Trends, Growth Factors and Opportunities

7.3.2 Top Key Companies

7.3.3 Historic and Forecasted Market Size by Segments

7.3.4 Historic and Forecasted Market Size by Product

7.3.4.1 CAM Software

7.3.4.2 CAD Software

7.3.4.3 CAE Software

7.3.5 Historic and Forecasted Market Size by Application

7.3.5.1 Drills

7.3.5.2 Boring Tools

7.3.5.3 Lathes

7.3.5.4 Other

7.3.6 Historic and Forecast Market Size by Country

7.3.6.1 Russia

7.3.6.2 Bulgaria

7.3.6.3 The Czech Republic

7.3.6.4 Hungary

7.3.6.5 Poland

7.3.6.6 Romania

7.3.6.7 Rest of Eastern Europe

7.4. Western Europe CNC Software Market

7.4.1 Key Market Trends, Growth Factors and Opportunities

7.4.2 Top Key Companies

7.4.3 Historic and Forecasted Market Size by Segments

7.4.4 Historic and Forecasted Market Size by Product

7.4.4.1 CAM Software

7.4.4.2 CAD Software

7.4.4.3 CAE Software

7.4.5 Historic and Forecasted Market Size by Application

7.4.5.1 Drills

7.4.5.2 Boring Tools

7.4.5.3 Lathes

7.4.5.4 Other

7.4.6 Historic and Forecast Market Size by Country

7.4.6.1 Germany

7.4.6.2 UK

7.4.6.3 France

7.4.6.4 The Netherlands

7.4.6.5 Italy

7.4.6.6 Spain

7.4.6.7 Rest of Western Europe

7.5. Asia Pacific CNC Software Market

7.5.1 Key Market Trends, Growth Factors and Opportunities

7.5.2 Top Key Companies

7.5.3 Historic and Forecasted Market Size by Segments

7.5.4 Historic and Forecasted Market Size by Product

7.5.4.1 CAM Software

7.5.4.2 CAD Software

7.5.4.3 CAE Software

7.5.5 Historic and Forecasted Market Size by Application

7.5.5.1 Drills

7.5.5.2 Boring Tools

7.5.5.3 Lathes

7.5.5.4 Other

7.5.6 Historic and Forecast Market Size by Country

7.5.6.1 China

7.5.6.2 India

7.5.6.3 Japan

7.5.6.4 South Korea

7.5.6.5 Malaysia

7.5.6.6 Thailand

7.5.6.7 Vietnam

7.5.6.8 The Philippines

7.5.6.9 Australia

7.5.6.10 New Zealand

7.5.6.11 Rest of APAC

7.6. Middle East & Africa CNC Software Market

7.6.1 Key Market Trends, Growth Factors and Opportunities

7.6.2 Top Key Companies

7.6.3 Historic and Forecasted Market Size by Segments

7.6.4 Historic and Forecasted Market Size by Product

7.6.4.1 CAM Software

7.6.4.2 CAD Software

7.6.4.3 CAE Software

7.6.5 Historic and Forecasted Market Size by Application

7.6.5.1 Drills

7.6.5.2 Boring Tools

7.6.5.3 Lathes

7.6.5.4 Other

7.6.6 Historic and Forecast Market Size by Country

7.6.6.1 Turkiye

7.6.6.2 Bahrain

7.6.6.3 Kuwait

7.6.6.4 Saudi Arabia

7.6.6.5 Qatar

7.6.6.6 UAE

7.6.6.7 Israel

7.6.6.8 South Africa

7.7. South America CNC Software Market

7.7.1 Key Market Trends, Growth Factors and Opportunities

7.7.2 Top Key Companies

7.7.3 Historic and Forecasted Market Size by Segments

7.7.4 Historic and Forecasted Market Size by Product

7.7.4.1 CAM Software

7.7.4.2 CAD Software

7.7.4.3 CAE Software

7.7.5 Historic and Forecasted Market Size by Application

7.7.5.1 Drills

7.7.5.2 Boring Tools

7.7.5.3 Lathes

7.7.5.4 Other

7.7.6 Historic and Forecast Market Size by Country

7.7.6.1 Brazil

7.7.6.2 Argentina

7.7.6.3 Rest of SA

Chapter 8 Analyst Viewpoint and Conclusion

8.1 Recommendations and Concluding Analysis

8.2 Potential Market Strategies

Chapter 9 Research Methodology

9.1 Research Process

9.2 Primary Research

9.3 Secondary Research

|

Global CNC Software Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 3.12 Bn. |

|

Forecast Period 2024-32 CAGR: |

2.80% |

Market Size in 2032: |

USD 3.90 Bn. |

|

Segments Covered: |

By Product |

|

|

|

By Application |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||