3D Printing Automotive Market Synopsis

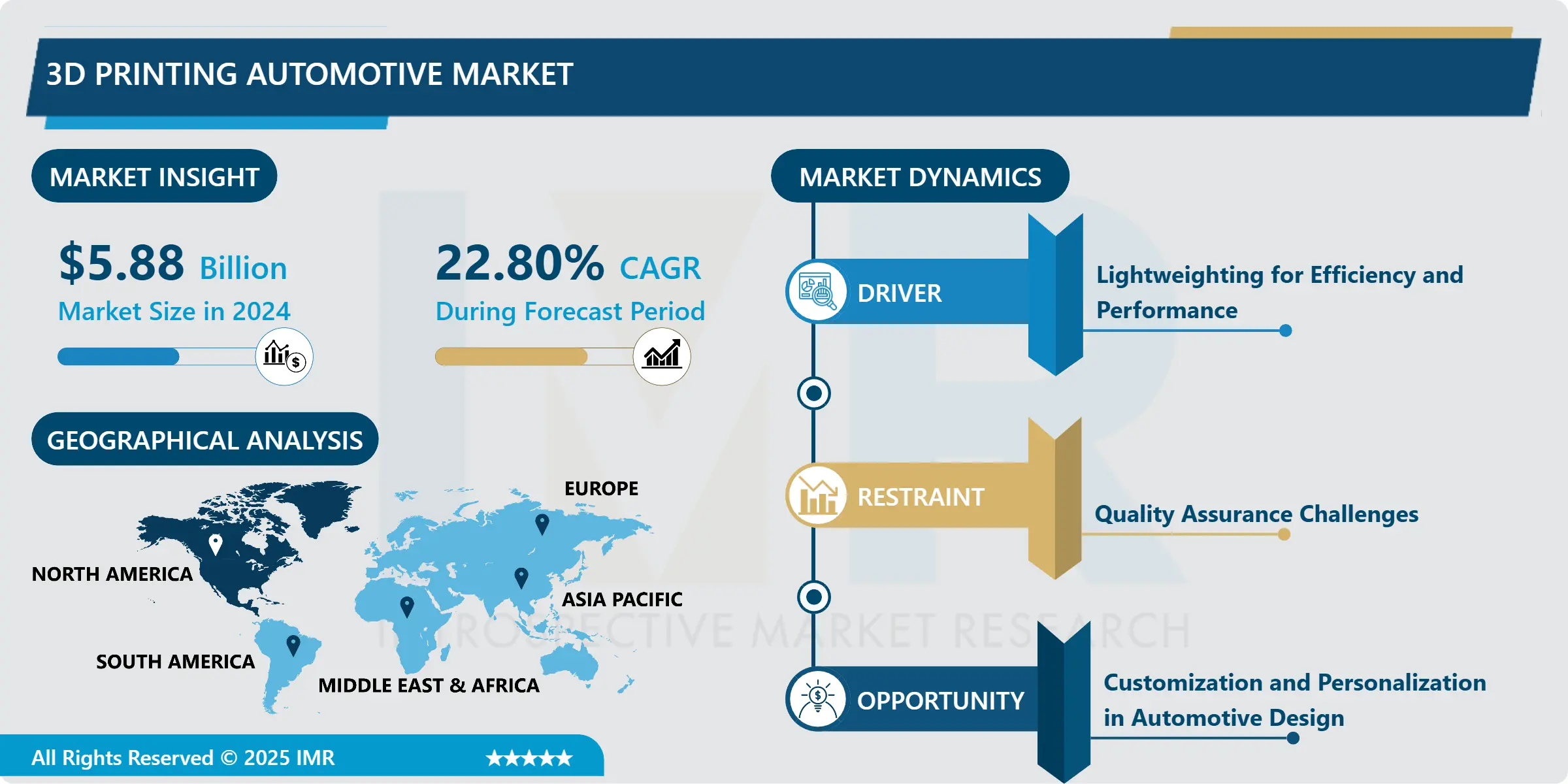

3D Printing Automotive Market Size Was Valued at USD 5.88 Billion in 2024 and is Projected to Reach USD 30.41 Billion by 2032, Growing at a CAGR of 22.80% From 2025-2032.

In automotive context, 3D printing is defined as the utilization of additive manufacturing techniques in fashioning of various hues and parts of automobiles. It involves adding up sheeting with materials like plastic, metals or composites to develop parts and sophisticated structures in 3D geometry. Automotive companies embrace 3D printing to develop concepts, build tools, make finished parts, customized trims and accessories, body panels among other automobile parts such as engines. It has some advantages such as relatively short time to produce parts, economical for small-batch production, and diverse attempts can be made for parts with complicated cross-sectional shapes. In a broad sense, the role of 3D printing can be reveled to be a revolutionary tool in enhancing the automotive industry through design , manufacture and performance improvements.

The application of 3D printing on automobiles has seen tremendous growth and evolution over the last years, triggered by various factors such as ; Technological Developments, Cost Control and best Practices and Final use. This disruptive technology is redefining the conventional nature of automobile manufacturing by providing control and ease of designing automobiles that were previously impossible to manufacture, almost real-time modeling, and chain management.

Some of the forces that are the most important in the case of the global 3D printing automotive market include the fact that it can allow for cost elimination in the case of producing intricate and unique components. 3D part production is usually a digital process as opposed to the traditional, more imposing manufacturing techniques that provide hefty tools and long lead times for automotive makers planning to create an original part. This also increases production efficiency thus acting as Cost effective since it helps in using minimal resources and at the same time helps achieve the concept of ‘Right the first time’ through the use of day to day iteration thus helping to meet the principle of meeting the demands of the customer.

Furthermore, it has opened the doors to the automotive industry in terms of the design possibilities provided by 3D printing to increase constructiveness, thin structures, complex shapes, and embedded functionalities. The use of hi-performance materials including polymers, support metals and composites empowers the automotive original equipment manufacturers to deliver on part performance, life and efficiency and with least wastage on material. This has resulted in the creation of advanced solutions in key elements of vehicle design, including lightweighting, aerodynamic improvements and thermal control, all of which converge to improve the vehicle’s performance and fuel efficiency.

In the same vein, it is worth pinpointing that 3D printing is actively contributing to supply chain improvements in the automotive sector on top of enabling improvements in product design and performance. Essentially, the use of 3D printing in the manufacturing process eliminates the need for extended supply chain structures, thereby avoiding challenges that may be occasioned by transport hiccups, stocked out inventories, or even political instabilities. Additionally, various other advanced technologies like selective laser sintering and fused deposition modeling allow ‘on-demand’ manufacturing of spare and replacement parts, thereby decreasing the inventory holding cost and enhancing the subsequent operational efficiency in the aftermarket services support.

Nevertheless, the current use of 3D printing in ways that are applicable to the automotive industry is not without some drawbacks and constraints. Among these is the issue of the speed to scale up the current additive manufacturing processes to support the volumes needed to produce mass market vehicle solutions. In terms of manufacturing small to moderately sized, intricate components, 3D printing has its advantages but cannot convincingly compete with the performance and economy of traditional large-scale production technologies. However, costly investments in high-end industrial type 3D printing machinery and materials helps in ensuring quality repetitive production but can hamper the adoption by small automotive manufacturing companies.

As a result, the 3D printing automotive is slated for further development and expansion in the future since the innovations in technology help to overcome existing drawbacks and embrace ahead of opportunities. These areas include the enhancement of the speed and cost of 3D printing, increased versatility of the materials used in 3D printing for highly demanding automotive applications, and the ability to incorporate 3D printing as part of digital-model manufacturing. Exploring the best use of 3D printing for automobiles creates an unprecedented opportunity for the design of new cars and supply chain flexibility of automotive companies for the automotive industry of the next generation.

3D Printing Automotive Market Trend Analysis

3D Printing Automotive Market Growth Drivers- Lightweighting for Efficiency and Performance

- Reduction of mass in automobile production is more often the weight reduction strategy that has vital goals of increasing efficiency while enhancing the performance of automobile products. Lighting technology has been revamped by the use of 3D Printing technology in this case providing this technique with differences to other traditional techniques of manufacturing. In this way, through the application of three-dimensional printing carbon fiber reinforced polymers or other advanced alloys, inventions with special shapes and structures that can be optimal for strength and hardness, but with minimum mass, can be produced. This way, it trimmed down weight that ultimately benefits manufacturers in terms of fuel efficiency as well as mechanicals such as acceleration, handling and braking mechanism.

- Further, the flexibility of building components on-demand from the powder bed and on-demand reduces lead-time, and cost in the auto making manufacturing process. Going forward, the automotive industry as a whole is bound to place even greater focus on sustainability and innovation, and in this context, 3D printing is all but certain to be called on to guide further approaches to sophisticated lightweighting

???????3D Printing Automotive Market Opportunities- Customization and Personalization in Automotive Design

- This particular factor can be ascertained with that of customization and personalization as the key trends in the automotive industry, primarily due to the progress made in 3D printers. This prevailing technology opens up the possibility of manufacturing many parts with a higher complexity of design and optimization in fulfilling consumer demand for customization. In the automotive industry, through 3D printing, you get to build components for cars including interior and exterior trims which effectively means that consumers are now free to buy cars that are customized to their specific tastes. Ranging from the individual dashboard highlight colors to the unique grille designs, almost every car part can be modified to your own taste and need.

- Further, 3D printing allows for better control of the prototyping and the design cycle, by enabling the manufacturers to rapidly bring new ideas to the market after receiving feedback from the clients. It also helps in continually improving or creating new products to better cater to customers’ needs, which in turn lead to the advancement of the automotive industry and the shift towards more customer-oriented designs. It can be seen that as 3D printing progresses in advance, the applied range in automotive will have the potential to develop more widely, which may lead the automotive design and manufacturing in the future.

3D Printing Automotive Market Segment Analysis:

3D Printing Automotive Market is segmented based on Technology Type, Component Type, Material and Application

By Technology Type, Digital Light Processing (DLP) segment is expected to dominate the market during the forecast period

- The 3D printing for the automotive vertical is experiencing rapid changes, with numerous types of technology such as Selective Laser Sintering (SLS), Stereo Lithography (SLA), Digital Light Processing(DLP), Electronic Beam Melting (EBM), Selective Laser Melting (SLM) and Fused Deposition Modeling(FDM) active. In turn, each of these technologies has its advantages: increased precision and surface quality, fast prototyping, and the possibility to cut the cost, respectively. For example, SLS and SLA are particularly good at detail and intricate geometries because of their accuracy in their production, making them appropriate for manufacturing prototypes and automobile parts.

- At the same time, DLP and FDM technologies are ranked high by the velocity of the process and relative cost, so they can be used in manufacturing functional parts and tools. Whereas EBM and SLM are preferred because they can deal with metal materials to produce automotive parts with full sturdiness and high-performing properties. Given ongoing advances in the topology optimization of parts, the application of these various forms of 3D printing will continue to advance in the auto production landscape, further energizing product development as well as production workflow advancements in the automotive field.

By Material, Metal segment held the largest share in 2024

- It is imperative to understand that in the sector of 3D Printing for cars each of the consecutive material types has its unique position in the automotive 3D Printing market. Metals because of their hardness are used for construction of engine components, chassis parts and structural moulded parts it being capable of withstanding high heat and pressures. Polymers are malleable structures and are cheaper compared to composite materials they are used in making interior parts, exterior shells, complex contours due to their lightweight nature and easiness in mold making.

- In the same regard, ceramics that are characterized by high heat resistance and electrical insulation are being used widely in the manufacture of production of brake assemblies, engine formed parts and exhaust systems in-order to increase the effectiveness and endurance of vehicles. With time and advancement of the 3D printing automotive market, more of these material types is being incorporated in these automotive 3D printers which act as a major boost to the manufacturing processes within industry.

3D Printing Automotive Market Regional Insights:

North America is Expected to Dominate the Market Over the Forecast period

- As for the expected growth of the 3D printing automotive market, North America is expected to retain its leading positions in the coming period, owing to a number of factors. Initially, it should be emphasized that the region possesses a developed and competitive automotive industry, in which manufacturers are constantly in search of new opportunities for improving the production processes or lowering the expenditures. Also, the regions that comprises North America has vast supply chain and several research institute working on improving the Additive Manufacturing technologies that is being supported by government imitative.

- Moreover, the growing use of 3D printers for automotive prototypes, tools and even car parts is possible to be attributed to the market as auto makers advance to realize the advantages of creating multiplying with the help of additive manufacturing technologies. Furthermore, the region’s awareness of sustainability and environmental issues is also complements with aspects of sustainable 3D printing makes it ideal for car manufacturers to integrate within automotive production lines. Currently, the 3D printing automotive market has a favourable regulation and generates many innovations; therefore, North America is set to retain the leadership over the foreseeable period, stimulating innovative technological advances and the modification of modern automotive production.

Active Key Players in the 3D Printing Automotive Market

- Stratasys (Israel)

- 3D Systems (US)

- EOS (Germany)

- Arcam AB (Sweden)

- Renishaw plc. (UK)

- HP (US)

- Materialise (Belgium)

- Desktop Metal (US)

- Carbon (US)

- SLM Solutions Group AG (Germany)

- Voxeljet (Germany)

- Farsoon Technologies (China)

- Sinterit (Poland)

- Protolabs (US)

- , Nexa3D (US)

- EPlus3D (China)

- Ultimaker (Netherlands) Other Active Players

Key Industry Developments in the 3D Printing Automotive Market

- In April 2024, Materialise, a global leader in 3D printing software and services, and Renishaw, a global engineering technologies company, announced a partnership to increase efficiency and productivity for manufacturers using Renishaw's additive manufacturing (AM) systems. Through the partnership, Renishaw system users will benefit from Materialise's next-generation build processor software tailored to the RenAM 500 series of metal AM systems.

- In April 2023, Stratasys Ltd. a global leader in polymer 3D printing solutions, announced the successful completion of its acquisition of the additive manufacturing materials business from Covestro AG This strategic acquisition, which was immediately accretive, significantly enhances Stratasys' materials portfolio and technological capabilities.

|

Global 3D Printing Automotive Market |

|||

|

Base Year: |

2024 |

Forecast Period: |

2025-2032 |

|

Historical Data: |

2018 to 2023 |

Market Size in 2023: |

USD 5.88 Bn. |

|

Forecast Period 2024-32 CAGR: |

22.80% |

Market Size in 2032: |

USD 30.41 Bn. |

|

Segments Covered: |

By Technology type |

|

|

|

By Component type |

|

||

|

By Material Type |

|

||

|

By Application |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

Chapter 1: Introduction

1.1 Scope and Coverage

Chapter 2:Executive Summary

Chapter 3: Market Landscape

3.1 Market Dynamics

3.1.1 Drivers

3.1.2 Restraints

3.1.3 Opportunities

3.1.4 Challenges

3.2 Market Trend Analysis

3.3 PESTLE Analysis

3.4 Porter's Five Forces Analysis

3.5 Industry Value Chain Analysis

3.6 Ecosystem

3.7 Regulatory Landscape

3.8 Price Trend Analysis

3.9 Patent Analysis

3.10 Technology Evolution

3.11 Investment Pockets

3.12 Import-Export Analysis

Chapter 4: 3D Printing Automotive Market by Technology type (2018-2032)

4.1 3D Printing Automotive Market Snapshot and Growth Engine

4.2 Market Overview

4.3 Selective Laser Sintering (SLS)

4.3.1 Introduction and Market Overview

4.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

4.3.3 Key Market Trends, Growth Factors, and Opportunities

4.3.4 Geographic Segmentation Analysis

4.4 Stereo Lithography (SLA)

4.5 Digital Light Processing (DLP)

4.6 Electronic Beam Melting (EBM)

4.7 Selective Laser Melting (SLM)

4.8 Fused Deposition Modeling (FDM)

Chapter 5: 3D Printing Automotive Market by Component type (2018-2032)

5.1 3D Printing Automotive Market Snapshot and Growth Engine

5.2 Market Overview

5.3 Hardware

5.3.1 Introduction and Market Overview

5.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

5.3.3 Key Market Trends, Growth Factors, and Opportunities

5.3.4 Geographic Segmentation Analysis

5.4 Software

5.5 Service

Chapter 6: 3D Printing Automotive Market by Material Type (2018-2032)

6.1 3D Printing Automotive Market Snapshot and Growth Engine

6.2 Market Overview

6.3 Metal

6.3.1 Introduction and Market Overview

6.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

6.3.3 Key Market Trends, Growth Factors, and Opportunities

6.3.4 Geographic Segmentation Analysis

6.4 Polymer

6.5 ceramic

Chapter 7: 3D Printing Automotive Market by Application (2018-2032)

7.1 3D Printing Automotive Market Snapshot and Growth Engine

7.2 Market Overview

7.3 production

7.3.1 Introduction and Market Overview

7.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

7.3.3 Key Market Trends, Growth Factors, and Opportunities

7.3.4 Geographic Segmentation Analysis

7.4 prototyping/R&D

Chapter 8: Company Profiles and Competitive Analysis

8.1 Competitive Landscape

8.1.1 Competitive Benchmarking

8.1.2 3D Printing Automotive Market Share by Manufacturer (2024)

8.1.3 Industry BCG Matrix

8.1.4 Heat Map Analysis

8.1.5 Mergers and Acquisitions

8.2 STRATASYS (ISRAEL)

8.2.1 Company Overview

8.2.2 Key Executives

8.2.3 Company Snapshot

8.2.4 Role of the Company in the Market

8.2.5 Sustainability and Social Responsibility

8.2.6 Operating Business Segments

8.2.7 Product Portfolio

8.2.8 Business Performance

8.2.9 Key Strategic Moves and Recent Developments

8.2.10 SWOT Analysis

8.3 3D SYSTEMS (US)

8.4 EOS (GERMANY)

8.5 ARCAM AB (SWEDEN)

8.6 RENISHAW PLC. (UK)

8.7 HP (US)

8.8 MATERIALISE (BELGIUM)

8.9 DESKTOP METAL (US)

8.10 CARBON (US)

8.11 SLM SOLUTIONS GROUP AG (GERMANY)

8.12 VOXELJET (GERMANY)

8.13 FARSOON TECHNOLOGIES (CHINA)

8.14 SINTERIT (POLAND)

8.15 PROTOLABS (US)

8.16

8.17 NEXA3D (US)

8.18 EPLUS3D (CHINA)

8.19 ULTIMAKER(NETHERLANDS) OTHER KEY PLAYERS

Chapter 9: Global 3D Printing Automotive Market By Region

9.1 Overview

9.2. North America 3D Printing Automotive Market

9.2.1 Key Market Trends, Growth Factors and Opportunities

9.2.2 Top Key Companies

9.2.3 Historic and Forecasted Market Size by Segments

9.2.4 Historic and Forecasted Market Size by Technology type

9.2.4.1 Selective Laser Sintering (SLS)

9.2.4.2 Stereo Lithography (SLA)

9.2.4.3 Digital Light Processing (DLP)

9.2.4.4 Electronic Beam Melting (EBM)

9.2.4.5 Selective Laser Melting (SLM)

9.2.4.6 Fused Deposition Modeling (FDM)

9.2.5 Historic and Forecasted Market Size by Component type

9.2.5.1 Hardware

9.2.5.2 Software

9.2.5.3 Service

9.2.6 Historic and Forecasted Market Size by Material Type

9.2.6.1 Metal

9.2.6.2 Polymer

9.2.6.3 ceramic

9.2.7 Historic and Forecasted Market Size by Application

9.2.7.1 production

9.2.7.2 prototyping/R&D

9.2.8 Historic and Forecast Market Size by Country

9.2.8.1 US

9.2.8.2 Canada

9.2.8.3 Mexico

9.3. Eastern Europe 3D Printing Automotive Market

9.3.1 Key Market Trends, Growth Factors and Opportunities

9.3.2 Top Key Companies

9.3.3 Historic and Forecasted Market Size by Segments

9.3.4 Historic and Forecasted Market Size by Technology type

9.3.4.1 Selective Laser Sintering (SLS)

9.3.4.2 Stereo Lithography (SLA)

9.3.4.3 Digital Light Processing (DLP)

9.3.4.4 Electronic Beam Melting (EBM)

9.3.4.5 Selective Laser Melting (SLM)

9.3.4.6 Fused Deposition Modeling (FDM)

9.3.5 Historic and Forecasted Market Size by Component type

9.3.5.1 Hardware

9.3.5.2 Software

9.3.5.3 Service

9.3.6 Historic and Forecasted Market Size by Material Type

9.3.6.1 Metal

9.3.6.2 Polymer

9.3.6.3 ceramic

9.3.7 Historic and Forecasted Market Size by Application

9.3.7.1 production

9.3.7.2 prototyping/R&D

9.3.8 Historic and Forecast Market Size by Country

9.3.8.1 Russia

9.3.8.2 Bulgaria

9.3.8.3 The Czech Republic

9.3.8.4 Hungary

9.3.8.5 Poland

9.3.8.6 Romania

9.3.8.7 Rest of Eastern Europe

9.4. Western Europe 3D Printing Automotive Market

9.4.1 Key Market Trends, Growth Factors and Opportunities

9.4.2 Top Key Companies

9.4.3 Historic and Forecasted Market Size by Segments

9.4.4 Historic and Forecasted Market Size by Technology type

9.4.4.1 Selective Laser Sintering (SLS)

9.4.4.2 Stereo Lithography (SLA)

9.4.4.3 Digital Light Processing (DLP)

9.4.4.4 Electronic Beam Melting (EBM)

9.4.4.5 Selective Laser Melting (SLM)

9.4.4.6 Fused Deposition Modeling (FDM)

9.4.5 Historic and Forecasted Market Size by Component type

9.4.5.1 Hardware

9.4.5.2 Software

9.4.5.3 Service

9.4.6 Historic and Forecasted Market Size by Material Type

9.4.6.1 Metal

9.4.6.2 Polymer

9.4.6.3 ceramic

9.4.7 Historic and Forecasted Market Size by Application

9.4.7.1 production

9.4.7.2 prototyping/R&D

9.4.8 Historic and Forecast Market Size by Country

9.4.8.1 Germany

9.4.8.2 UK

9.4.8.3 France

9.4.8.4 The Netherlands

9.4.8.5 Italy

9.4.8.6 Spain

9.4.8.7 Rest of Western Europe

9.5. Asia Pacific 3D Printing Automotive Market

9.5.1 Key Market Trends, Growth Factors and Opportunities

9.5.2 Top Key Companies

9.5.3 Historic and Forecasted Market Size by Segments

9.5.4 Historic and Forecasted Market Size by Technology type

9.5.4.1 Selective Laser Sintering (SLS)

9.5.4.2 Stereo Lithography (SLA)

9.5.4.3 Digital Light Processing (DLP)

9.5.4.4 Electronic Beam Melting (EBM)

9.5.4.5 Selective Laser Melting (SLM)

9.5.4.6 Fused Deposition Modeling (FDM)

9.5.5 Historic and Forecasted Market Size by Component type

9.5.5.1 Hardware

9.5.5.2 Software

9.5.5.3 Service

9.5.6 Historic and Forecasted Market Size by Material Type

9.5.6.1 Metal

9.5.6.2 Polymer

9.5.6.3 ceramic

9.5.7 Historic and Forecasted Market Size by Application

9.5.7.1 production

9.5.7.2 prototyping/R&D

9.5.8 Historic and Forecast Market Size by Country

9.5.8.1 China

9.5.8.2 India

9.5.8.3 Japan

9.5.8.4 South Korea

9.5.8.5 Malaysia

9.5.8.6 Thailand

9.5.8.7 Vietnam

9.5.8.8 The Philippines

9.5.8.9 Australia

9.5.8.10 New Zealand

9.5.8.11 Rest of APAC

9.6. Middle East & Africa 3D Printing Automotive Market

9.6.1 Key Market Trends, Growth Factors and Opportunities

9.6.2 Top Key Companies

9.6.3 Historic and Forecasted Market Size by Segments

9.6.4 Historic and Forecasted Market Size by Technology type

9.6.4.1 Selective Laser Sintering (SLS)

9.6.4.2 Stereo Lithography (SLA)

9.6.4.3 Digital Light Processing (DLP)

9.6.4.4 Electronic Beam Melting (EBM)

9.6.4.5 Selective Laser Melting (SLM)

9.6.4.6 Fused Deposition Modeling (FDM)

9.6.5 Historic and Forecasted Market Size by Component type

9.6.5.1 Hardware

9.6.5.2 Software

9.6.5.3 Service

9.6.6 Historic and Forecasted Market Size by Material Type

9.6.6.1 Metal

9.6.6.2 Polymer

9.6.6.3 ceramic

9.6.7 Historic and Forecasted Market Size by Application

9.6.7.1 production

9.6.7.2 prototyping/R&D

9.6.8 Historic and Forecast Market Size by Country

9.6.8.1 Turkiye

9.6.8.2 Bahrain

9.6.8.3 Kuwait

9.6.8.4 Saudi Arabia

9.6.8.5 Qatar

9.6.8.6 UAE

9.6.8.7 Israel

9.6.8.8 South Africa

9.7. South America 3D Printing Automotive Market

9.7.1 Key Market Trends, Growth Factors and Opportunities

9.7.2 Top Key Companies

9.7.3 Historic and Forecasted Market Size by Segments

9.7.4 Historic and Forecasted Market Size by Technology type

9.7.4.1 Selective Laser Sintering (SLS)

9.7.4.2 Stereo Lithography (SLA)

9.7.4.3 Digital Light Processing (DLP)

9.7.4.4 Electronic Beam Melting (EBM)

9.7.4.5 Selective Laser Melting (SLM)

9.7.4.6 Fused Deposition Modeling (FDM)

9.7.5 Historic and Forecasted Market Size by Component type

9.7.5.1 Hardware

9.7.5.2 Software

9.7.5.3 Service

9.7.6 Historic and Forecasted Market Size by Material Type

9.7.6.1 Metal

9.7.6.2 Polymer

9.7.6.3 ceramic

9.7.7 Historic and Forecasted Market Size by Application

9.7.7.1 production

9.7.7.2 prototyping/R&D

9.7.8 Historic and Forecast Market Size by Country

9.7.8.1 Brazil

9.7.8.2 Argentina

9.7.8.3 Rest of SA

Chapter 10 Analyst Viewpoint and Conclusion

10.1 Recommendations and Concluding Analysis

10.2 Potential Market Strategies

Chapter 11 Research Methodology

11.1 Research Process

11.2 Primary Research

11.3 Secondary Research

|

Global 3D Printing Automotive Market |

|||

|

Base Year: |

2024 |

Forecast Period: |

2025-2032 |

|

Historical Data: |

2018 to 2023 |

Market Size in 2023: |

USD 5.88 Bn. |

|

Forecast Period 2024-32 CAGR: |

22.80% |

Market Size in 2032: |

USD 30.41 Bn. |

|

Segments Covered: |

By Technology type |

|

|

|

By Component type |

|

||

|

By Material Type |

|

||

|

By Application |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||