Global Metal Injection Molding (MIM) Market Overview

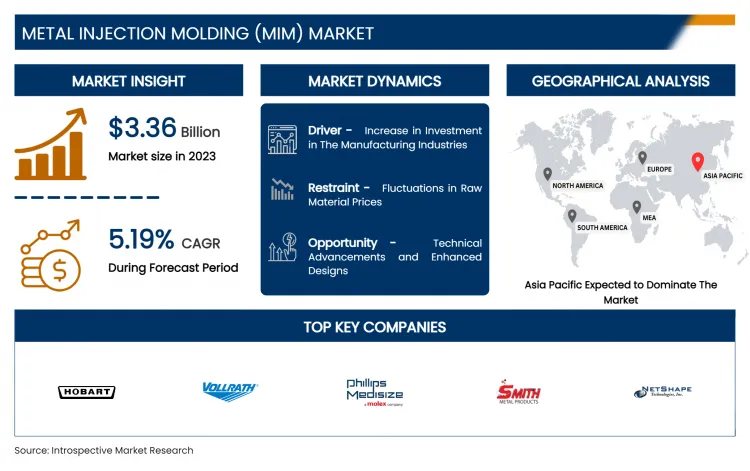

Metal Injection Molding (MIM) Market size is expected to grow from USD 3.53 Billion in 2024 to USD 5.29 Billion by 2032, at a CAGR of 5.19% during the forecast period 2025–2032.

Metal Injection Molding (MIM) represents a manufacturing process that marries the adaptability of plastic injection molding with the robustness of metal materials. This method entails shaping intricate metal components by injecting a blend of metal powder and a polymer binder into a mold. Subsequently, the mixture undergoes a heating process to eliminate the binder and is sintered to consolidate the metal particles, resulting in a cohesive metal piece. MIM is particularly well-suited for the production of small, intricately shaped components that would be challenging or expensive to manufacture using conventional methods. Metal Injection Molding finds applications across diverse industries, including automotive, aerospace, medical, electronics, and consumer goods. MIM is instrumental in crafting components like gears, brackets, and connectors within the automotive sector, leveraging its capacity to form intricate geometries while maintaining high strength. In the medical field, MIM is integral to the fabrication of surgical instruments and implants, capitalizing on its ability to produce small, complex, and biocompatible metal parts. Furthermore, the electronics industry embraces MIM for manufacturing connectors, switches, and other precision-dependent components.

A prominent advantage of Metal Injection Molding lies in its cost-effectiveness for the mass production of small, intricate parts. MIM facilitates the production of components with elevated accuracy and consistency, diminishing the need for secondary machining operations. Additionally, the process accommodates a broad spectrum of materials, encompassing stainless steel, titanium, and various alloys, affording flexibility in material selection based on the desired properties of the final component. The capability to craft intricate designs and achieve tight tolerances, coupled with the efficiency of batch production, positions Metal Injection Molding as a valuable technology for industries seeking economical solutions for intricate metal parts.

Metal Injection Molding (MIM) Market Trend Analysis:

Increase in Investment in The Manufacturing Industries

- The Metal Injection Molding (MIM) market is witnessing significant growth, driven by a surge in investments in the manufacturing industries. As industries undergo expansion and modernization, there is an increasing demand for manufacturing processes that are both efficient and cost-effective, making MIM an advantageous solution. The infusion of investments enables manufacturing facilities to adopt and integrate MIM technology seamlessly into their production processes, thereby propelling the market's expansion.

- Investments in manufacturing industries catalyze the Metal Injection Molding market by facilitating the acquisition of advanced machinery and technology. MIM's capability to produce intricate metal components with high precision makes it particularly appealing to industries in search of innovative and streamlined manufacturing solutions. Financial support fosters research and development activities, leading to ongoing advancements in MIM processes and materials. Consequently, this enhances the market's appeal, with manufacturers leveraging these innovations to produce intricate parts across diverse sectors such as automotive, aerospace, medical, and electronics.

- Furthermore, the increased investment in manufacturing industries contributes to the scalability of Metal Injection Molding. With substantial capital injections, companies can optimize production capacities, implement robust quality control measures, and extend their market reach. This scalability not only bolsters the ongoing growth trajectory but also positions MIM as a robust and sustainable choice for the long term. The interdependent relationship between heightened investment in manufacturing and the expansion of the Metal Injection Molding market underscores the pivotal role MIM plays in addressing the evolving demands of modern industries.

Technical Advancements and Enhanced Designs

- The market for Metal Injection Molding (MIM) is poised for growth due to the promising opportunities presented by ongoing technical advancements and enhanced designs. As technology continues to evolve, MIM processes benefit from innovations that contribute to improved efficiency, precision, and cost-effectiveness. Technical advancements in materials, mold design, and production methods enable manufacturers to push the boundaries of what is achievable with MIM, expanding its applications across various industries.

- Enhanced designs represent a significant opportunity for the Metal Injection Molding market. The ability of MIM to produce intricate and complex geometries with high precision aligns with the growing demand for sophisticated and customized components. The continuous refinement of design capabilities in MIM opens doors to new possibilities, allowing for the creation of intricate parts that were once deemed challenging or impossible to manufacture. This is particularly relevant in industries such as aerospace, medical devices, and electronics, where intricate and precisely engineered components are crucial.

- Moreover, advancements in materials science contribute to the market's growth by expanding the range of materials compatible with MIM processes. This not only enhances the performance characteristics of the manufactured components but also widens the scope of potential applications. The synergy between technical advancements and enhanced designs creates a fertile ground for Metal Injection Molding, positioning it as a versatile and cutting-edge manufacturing solution that aligns with the evolving needs of diverse industries. As technology continues to progress, MIM stands to benefit from a continual cycle of innovation, driving its market growth and solidifying its role in the manufacturing landscape.

Metal Injection Molding (MIM) Market Segment Analysis:

Metal Injection Molding (MIM) Market Segmented on the basis of type, and End-users.

By End-User, Automotive segment is expected to dominate the market during the forecast Period

- The automotive sector's growing dependence on Metal Injection Molding (MIM) stems from its capability to manufacture intricate, high-precision components, fulfilling the industry's need for complex geometries and tailor-made parts. MIM's cost-effectiveness and operational efficiency are especially beneficial for automotive manufacturers exploring sophisticated solutions for gear systems, brackets, and engine components. The technology's adeptness in streamlining production processes seamlessly aligns with the automotive sector's focus on lightweight and improved fuel efficiency, significantly contributing to the market's expansion.

- Furthermore, MIM's role in automotive applications transcends conventional components, encompassing advanced safety features, sensor systems, and electronic components. As the automotive industry persists in prioritizing innovation and performance, the Metal Injection Molding market is poised for substantial growth, with the automotive segment leading the way through increased adoption and a broadening array of applications.

Metal Injection Molding (MIM) Market Regional Insights:

Asia Pacific is Expected to Dominate the Market Over the Forecast period

- Asia Pacific stands out as the predominant region propelling the Metal Injection Molding (MIM) market's growth. The region's industrial scenario, characterized by a flourishing automotive sector, electronics manufacturing, and advancements in materials technology, positions it as a key catalyst for MIM adoption. Asia Pacific, boasting a robust manufacturing ecosystem, leverages MIM processes' cost-effectiveness and precision advantages, making it the preferred choice across diverse industries. The increasing demand for intricate components in automotive and electronics, coupled with the region's strategic emphasis on innovative manufacturing solutions, further accelerates MIM's dominance in Asia Pacific.

- Furthermore, the region's pivotal role as a global manufacturing hub enhances its impact on the MIM market, with countries such as China, Japan, and South Korea leading the way in embracing advanced manufacturing technologies. With ongoing rapid industrialization and technological advancements, the Metal Injection Molding market in the Asia Pacific is poised for sustained growth, propelled by the region's dynamic manufacturing landscape and its central role in shaping the global supply chain.

Key Players Covered in Metal Injection Molding (MIM) Market:

- Dynacast International (U.S)

- ARC Group Worldwide (U.S.)

- Phillips-Medisize (U.S.)

- Smith Metal Products (U.S.)

- NetShape Technologies (U.S.)

- Parmatech Corporation (U.S.)

- Tritech Titanium Parts (U.S.)

- Cypress Industries (U.S.)

- ATW Companies (U.S.)

- Britt Manufacturing (U.S.)

- CMG Technologies (UK)

- Dean Group International (UK)

- GKN PLC (UK)

- Real Technik AG (Austria)

- Parmaco Metal Injection Molding AG (Switzerland)

- Ceratizit S.A.(Luxembourg)

- Sintex (China)

- Future High-Tech (China)

- TEKNA. (China)

- Epson Atmix Corporation (Japan)

- Hitachi Metals, Ltd. (Japan)

- Indo-MIM Pvt (India)

- Other Active Players

Key Industry Developments in the Metal Injection Molding (MIM) Market:

- In June 2023, TriTech Titanium Parts LLC, based out of Detroit, Michigan, and Tekna, a Canadian market leader, announced a strategic collaboration. Joint efforts by both companies resulted in successful binder-jetting of titanium parts with the use of a desktop metal P1 additive manufacturing machine. Titanium powder provider Tekna compliments the binder jet 3D printing capabilities of TriTech.

- In June 2023, Ceratizit, part of the CERATIZIT Group, which is a manufacturer of hard material products used for wear protection and cutting tools, announced that since the start of the year, the company has ensured production operations are conducted using 99% renewable energy sources. The company plans to become carbon-neutral by the end of 2025.

|

Global Metal Injection Molding (MIM) Market |

|||

|

Base Year: |

2024 |

Forecast Period: |

2025-2032 |

|

Historical Data: |

2018 to 2023 |

Market Size in 2024: |

USD 3.53 Bn. |

|

Forecast Period 2024-32 CAGR: |

5.19% |

Market Size in 2032: |

USD 5.29 Bn. |

|

Segments Covered: |

By Type |

|

|

|

By End Users |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

Chapter 1: Introduction

1.1 Scope and Coverage

Chapter 2:Executive Summary

Chapter 3: Market Landscape

3.1 Market Dynamics

3.1.1 Drivers

3.1.2 Restraints

3.1.3 Opportunities

3.1.4 Challenges

3.2 Market Trend Analysis

3.3 PESTLE Analysis

3.4 Porter's Five Forces Analysis

3.5 Industry Value Chain Analysis

3.6 Ecosystem

3.7 Regulatory Landscape

3.8 Price Trend Analysis

3.9 Patent Analysis

3.10 Technology Evolution

3.11 Investment Pockets

3.12 Import-Export Analysis

Chapter 4: Metal Injection Molding (MIM) Market by Type (2018-2032)

4.1 Metal Injection Molding (MIM) Market Snapshot and Growth Engine

4.2 Market Overview

4.3 Stainless Steel

4.3.1 Introduction and Market Overview

4.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

4.3.3 Key Market Trends, Growth Factors, and Opportunities

4.3.4 Geographic Segmentation Analysis

4.4 Low Alloy Steel

4.5 Soft Magnetic Material

4.6 Others

Chapter 5: Metal Injection Molding (MIM) Market by End Users (2018-2032)

5.1 Metal Injection Molding (MIM) Market Snapshot and Growth Engine

5.2 Market Overview

5.3 Electrical & Electronics

5.3.1 Introduction and Market Overview

5.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

5.3.3 Key Market Trends, Growth Factors, and Opportunities

5.3.4 Geographic Segmentation Analysis

5.4 Automotive

5.5 Medical & Orthodontics

5.6 Consumer Products

5.7 Industrial

5.8 Firearms & Defense

5.9 Others

Chapter 6: Company Profiles and Competitive Analysis

6.1 Competitive Landscape

6.1.1 Competitive Benchmarking

6.1.2 Metal Injection Molding (MIM) Market Share by Manufacturer (2024)

6.1.3 Industry BCG Matrix

6.1.4 Heat Map Analysis

6.1.5 Mergers and Acquisitions

6.2 PERFECT GYM SOLUTIONS

6.2.1 Company Overview

6.2.2 Key Executives

6.2.3 Company Snapshot

6.2.4 Role of the Company in the Market

6.2.5 Sustainability and Social Responsibility

6.2.6 Operating Business Segments

6.2.7 Product Portfolio

6.2.8 Business Performance

6.2.9 Key Strategic Moves and Recent Developments

6.2.10 SWOT Analysis

6.3 VERYCONNECT

6.4 ACS TECHNOLOGIES

6.5 DOXESS

6.6 DONORVIEW

6.7 CASTLAMP

6.8 RESERVIO

6.9 DAXKO

6.10 EVENTBANK

6.11 RECDESK

6.12 OLATECH

6.13 FUNDRAISER SOFTWARE

6.14 CLUB RIGHT

6.15 RAKLET

6.16 CAPTECK

6.17 GROWTHZONE

6.18 AND OTHER KEY PLAYERS

6.19

Chapter 7: Global Metal Injection Molding (MIM) Market By Region

7.1 Overview

7.2. North America Metal Injection Molding (MIM) Market

7.2.1 Key Market Trends, Growth Factors and Opportunities

7.2.2 Top Key Companies

7.2.3 Historic and Forecasted Market Size by Segments

7.2.4 Historic and Forecasted Market Size by Type

7.2.4.1 Stainless Steel

7.2.4.2 Low Alloy Steel

7.2.4.3 Soft Magnetic Material

7.2.4.4 Others

7.2.5 Historic and Forecasted Market Size by End Users

7.2.5.1 Electrical & Electronics

7.2.5.2 Automotive

7.2.5.3 Medical & Orthodontics

7.2.5.4 Consumer Products

7.2.5.5 Industrial

7.2.5.6 Firearms & Defense

7.2.5.7 Others

7.2.6 Historic and Forecast Market Size by Country

7.2.6.1 US

7.2.6.2 Canada

7.2.6.3 Mexico

7.3. Eastern Europe Metal Injection Molding (MIM) Market

7.3.1 Key Market Trends, Growth Factors and Opportunities

7.3.2 Top Key Companies

7.3.3 Historic and Forecasted Market Size by Segments

7.3.4 Historic and Forecasted Market Size by Type

7.3.4.1 Stainless Steel

7.3.4.2 Low Alloy Steel

7.3.4.3 Soft Magnetic Material

7.3.4.4 Others

7.3.5 Historic and Forecasted Market Size by End Users

7.3.5.1 Electrical & Electronics

7.3.5.2 Automotive

7.3.5.3 Medical & Orthodontics

7.3.5.4 Consumer Products

7.3.5.5 Industrial

7.3.5.6 Firearms & Defense

7.3.5.7 Others

7.3.6 Historic and Forecast Market Size by Country

7.3.6.1 Russia

7.3.6.2 Bulgaria

7.3.6.3 The Czech Republic

7.3.6.4 Hungary

7.3.6.5 Poland

7.3.6.6 Romania

7.3.6.7 Rest of Eastern Europe

7.4. Western Europe Metal Injection Molding (MIM) Market

7.4.1 Key Market Trends, Growth Factors and Opportunities

7.4.2 Top Key Companies

7.4.3 Historic and Forecasted Market Size by Segments

7.4.4 Historic and Forecasted Market Size by Type

7.4.4.1 Stainless Steel

7.4.4.2 Low Alloy Steel

7.4.4.3 Soft Magnetic Material

7.4.4.4 Others

7.4.5 Historic and Forecasted Market Size by End Users

7.4.5.1 Electrical & Electronics

7.4.5.2 Automotive

7.4.5.3 Medical & Orthodontics

7.4.5.4 Consumer Products

7.4.5.5 Industrial

7.4.5.6 Firearms & Defense

7.4.5.7 Others

7.4.6 Historic and Forecast Market Size by Country

7.4.6.1 Germany

7.4.6.2 UK

7.4.6.3 France

7.4.6.4 The Netherlands

7.4.6.5 Italy

7.4.6.6 Spain

7.4.6.7 Rest of Western Europe

7.5. Asia Pacific Metal Injection Molding (MIM) Market

7.5.1 Key Market Trends, Growth Factors and Opportunities

7.5.2 Top Key Companies

7.5.3 Historic and Forecasted Market Size by Segments

7.5.4 Historic and Forecasted Market Size by Type

7.5.4.1 Stainless Steel

7.5.4.2 Low Alloy Steel

7.5.4.3 Soft Magnetic Material

7.5.4.4 Others

7.5.5 Historic and Forecasted Market Size by End Users

7.5.5.1 Electrical & Electronics

7.5.5.2 Automotive

7.5.5.3 Medical & Orthodontics

7.5.5.4 Consumer Products

7.5.5.5 Industrial

7.5.5.6 Firearms & Defense

7.5.5.7 Others

7.5.6 Historic and Forecast Market Size by Country

7.5.6.1 China

7.5.6.2 India

7.5.6.3 Japan

7.5.6.4 South Korea

7.5.6.5 Malaysia

7.5.6.6 Thailand

7.5.6.7 Vietnam

7.5.6.8 The Philippines

7.5.6.9 Australia

7.5.6.10 New Zealand

7.5.6.11 Rest of APAC

7.6. Middle East & Africa Metal Injection Molding (MIM) Market

7.6.1 Key Market Trends, Growth Factors and Opportunities

7.6.2 Top Key Companies

7.6.3 Historic and Forecasted Market Size by Segments

7.6.4 Historic and Forecasted Market Size by Type

7.6.4.1 Stainless Steel

7.6.4.2 Low Alloy Steel

7.6.4.3 Soft Magnetic Material

7.6.4.4 Others

7.6.5 Historic and Forecasted Market Size by End Users

7.6.5.1 Electrical & Electronics

7.6.5.2 Automotive

7.6.5.3 Medical & Orthodontics

7.6.5.4 Consumer Products

7.6.5.5 Industrial

7.6.5.6 Firearms & Defense

7.6.5.7 Others

7.6.6 Historic and Forecast Market Size by Country

7.6.6.1 Turkiye

7.6.6.2 Bahrain

7.6.6.3 Kuwait

7.6.6.4 Saudi Arabia

7.6.6.5 Qatar

7.6.6.6 UAE

7.6.6.7 Israel

7.6.6.8 South Africa

7.7. South America Metal Injection Molding (MIM) Market

7.7.1 Key Market Trends, Growth Factors and Opportunities

7.7.2 Top Key Companies

7.7.3 Historic and Forecasted Market Size by Segments

7.7.4 Historic and Forecasted Market Size by Type

7.7.4.1 Stainless Steel

7.7.4.2 Low Alloy Steel

7.7.4.3 Soft Magnetic Material

7.7.4.4 Others

7.7.5 Historic and Forecasted Market Size by End Users

7.7.5.1 Electrical & Electronics

7.7.5.2 Automotive

7.7.5.3 Medical & Orthodontics

7.7.5.4 Consumer Products

7.7.5.5 Industrial

7.7.5.6 Firearms & Defense

7.7.5.7 Others

7.7.6 Historic and Forecast Market Size by Country

7.7.6.1 Brazil

7.7.6.2 Argentina

7.7.6.3 Rest of SA

Chapter 8 Analyst Viewpoint and Conclusion

8.1 Recommendations and Concluding Analysis

8.2 Potential Market Strategies

Chapter 9 Research Methodology

9.1 Research Process

9.2 Primary Research

9.3 Secondary Research

|

Global Metal Injection Molding (MIM) Market |

|||

|

Base Year: |

2024 |

Forecast Period: |

2025-2032 |

|

Historical Data: |

2018 to 2023 |

Market Size in 2024: |

USD 3.53 Bn. |

|

Forecast Period 2024-32 CAGR: |

5.19% |

Market Size in 2032: |

USD 5.29 Bn. |

|

Segments Covered: |

By Type |

|

|

|

By End Users |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

_Market.webp)