Level Sensor Market Synopsis

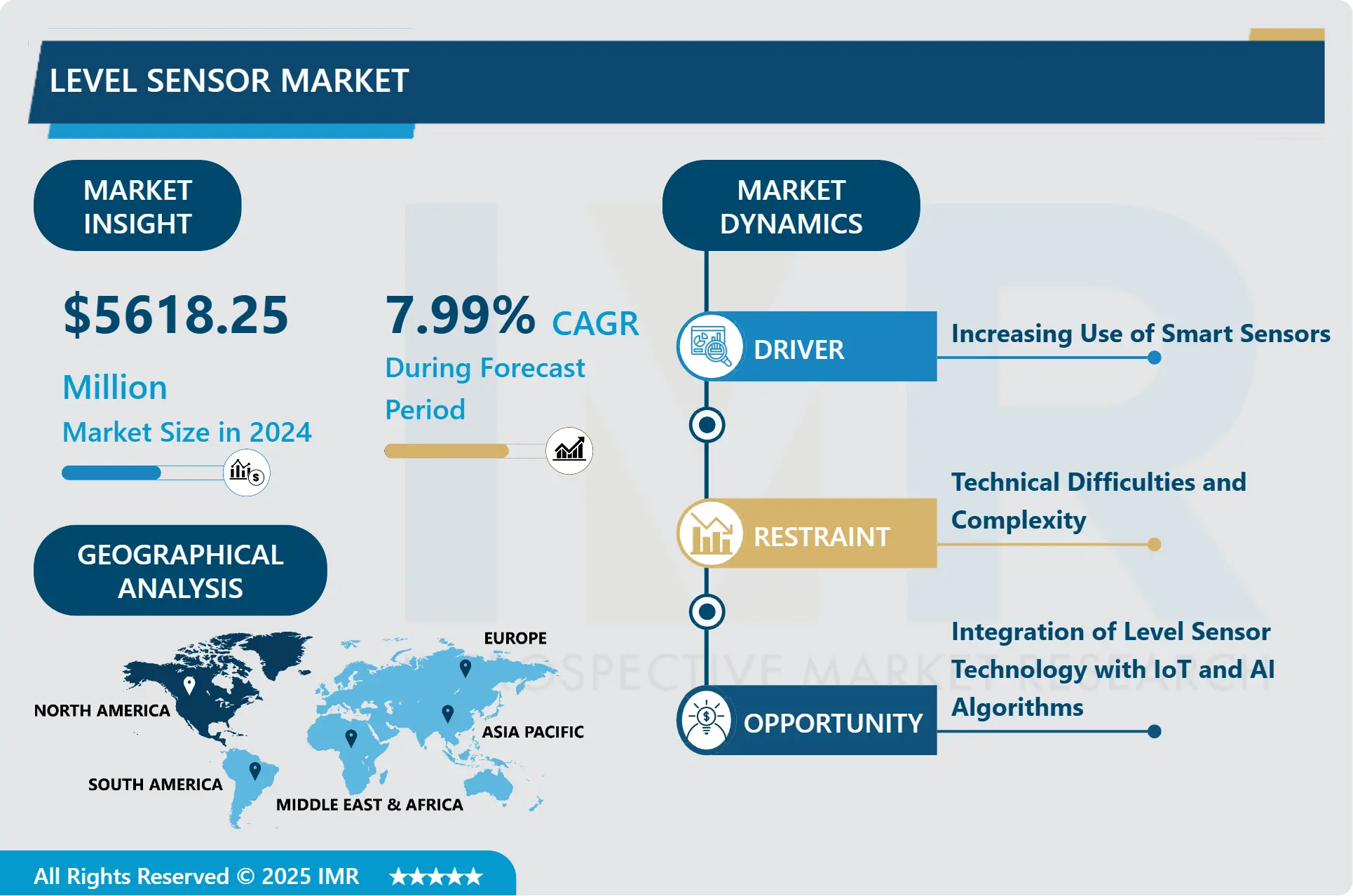

Level Sensor Market Size Was Valued at USD 5618.25 Million in 2024, and is Projected to Reach USD 10391.28 Million by 2032, Growing at a CAGR of 7.99% From 2025-2032.

A level sensor is a tool that is utilized to identify the level of substances such as liquids, powders, and granular materials in a container or area. These sensors are versatile tools that can be utilized in a range of applications to monitor and regulate material levels, guaranteeing the smooth and secure functioning of operations in industries such as manufacturing, water treatment, food and beverage, pharmaceuticals, and other sectors.

The demand for accurate level measurement tools such as sensors is increasing due to the rise of industrial automation, leading to reduced errors, enhanced efficiency, and improved safety in processes. The water and wastewater treatment sector are expanding as a result of an increased emphasis on sustainability and regulatory adherence. The Oil & Gas industry requires accurate level measurements for activities such as monitoring fuel levels in tanks and pipelines. The increase in the industry in developing markets drives the need for level sensors.

Technological advancements have enhanced the accuracy and cost-effectiveness of level sensors. Non-touch sensors equipped with IoT features are becoming increasingly popular, fuelling the expansion of the market. The food and beverage sector are utilizing level sensors for accurate measurement in production, storage, and packaging in order to maintain quality and consistency, leading to a higher rate of adoption in the industry. Effective management of water is vital, and level sensors are necessary for overseeing and regulating water levels.

Rising need in the pharmaceutical sector requires accurate monitoring of levels for quality assurance. Increased demand for level sensors is being driven by the growth in the production of vaccines and medications. Level sensors play a role in boosting market expansion by enhancing fuel monitoring and household appliance functionality in consumer electronics and automotive sectors.

Level Sensor Market Trend Analysis

Level Sensor Market Growth Driver- Increasing Use of Smart Sensors

- Smart sensors able to interconnect to IoT platforms and industrial networks for instant data transfer and remote level supervision. Integration of IoT enables improved analysis of data and decision-making in control systems. Smart sensors are constantly observing level measurements in industrial processes in order to detect any possible problems. Utilizing sophisticated analytics and machine learning, they identify patterns and anomalies to plan predictive maintenance. This enhances the dependability of equipment and decreases the amount of time it is not operational.

- Smart sensors offer immediate feedback on level gauges, enhancing effectiveness and output in various sectors. Operators have the capability to monitor inventory, track production processes, and allocate resources remotely using sensor data, resulting in quicker decision-making and improved resource utilization. These sensors make it possible for operators to remotely monitor and adjust level measurements using internet access from any location. This improves flexibility in operations, agility, and safety while also lowering labour expenses.

- Smart sensors play a crucial role in Industry 4.0 by facilitating smooth data sharing and compatibility between smart devices. They are responsible for driving digital transformation and automation in various industries, which improves efficiency and competitiveness. These sensors are more adaptable and expandable compared to conventional sensors, enabling tailored solutions for specific requirements and simple alterations for evolving demands. This allows for smooth integration into current systems to create tailored industry solutions. Smart sensors aid industries in meeting regulatory requirements through precise level measurements for environment monitoring, safety, and quality assurance, thereby decreasing the chances of facing penalties and fines for violating regulations.

Level Sensor Market Opportunity- Integration of Level Sensor Technology with IoT and AI Algorithms

- Level sensors utilizing IoT technology provide instant monitoring and distant access. Operators have the ability to check and track fluid levels from any location with an internet connection, enabling quick reactions to any alterations, enhancing productivity, and reducing downtime. AI algorithms use data collected from level sensors in IoT devices to anticipate equipment malfunctions or maintenance requirements. Anticipatory maintenance identifies trends in data to take proactive measures in minimizing downtime, cutting costs, and prolonging the life of equipment.

- Real-time surveillance, proactive upkeep, and insights based on data enhance operational effectiveness by streamlining procedures, reducing downtime, and lowering maintenance expenses. This results in savings, competitiveness, and improved customer satisfaction. AI algorithms examine past and present data to provide useful insights for improving operational efficiency and performance. Monitoring in real-time along with analytics driven by artificial intelligence provide understanding of fluid levels and patterns of consumption. This allows organizations to maximize resource distribution, cut down on waste, lower expenses, and guarantee effective resource utilization.

- IoT sensors for levels improve safety compliance by overseeing fluid levels and conditions, guaranteeing adherence to regulations. AI analytics have the capability to identify potential safety hazards and deviations, leading to the implementation of corrective measures aimed at reducing risks. The combination of IoT and AI improves the ability to adjust to operational requirements by increasing scalability. Organizations have the capability to easily grow their sensor infrastructure and adapt to evolving needs, smoothly integrating with current systems and preparing for future advancements.

Level Sensor Market Segment Analysis:

Level Sensor Market is segmented on the basis of Type, Technology, Monitoring Type, End-User, And Region.

By Type, Non-Contact Level Sensor Segment Is Expected to Dominate the Market During the Forecast Period

- The non-contact ultrasonic level sensors consist of elements, analogue signal processor, microprocessor, binary coded decimal (BCD) range switches, and an output driver circuit. The microprocessor generates a series of transmit pulses and a transmit gate signal that are routed through the analogue signal processor to the sensor. The sensor transmits an ultrasonic beam to the surface level, and the returned echo from the surface is detected by the sensor and routed to the microprocessor, which processes the signal into a digital representation of the distance between the sensor and the surface level.

- Improvements in sensor technology have significantly enhanced non-contact level sensors such as ultrasonic, radar, laser, and microwave sensors, expanding their accuracy, dependability, and range of uses beyond traditional contact sensors. Non-contact level sensors are adaptable and versatile, making them well-suited for a range of applications and industries. They are able to gauge liquids, solids, and granular materials without making physical contact, which is advantageous for industries such as food, beverage, and pharmaceuticals.

- Non-contact sensors need less upkeep than contact sensors because they do not touch the materials being measured, resulting in reduced wear and tear and decreased risk of damage. This leads to lower maintenance expenses and extended sensor durations, attracting industries focused on saving costs. industries such as medical, food, and beverage favour non-contact level sensors due to safety and hygiene reasons. They avoid touching materials to prevent contamination. In dangerous locations such as chemical plants, these sensors decrease the number of incidents.

By Technology, Ultrasonic Segment Held the Largest Share In 2024

- The ultrasonic sensor is a piezoelectric transducer, which is able to convert an electrical signal into mechanical vibrations, and mechanical vibrations into an electrical signal. Therefore, in a monostatic approach, the ultrasonic sensor is a transceiver which operates as both a speaker and microphone at a single frequency. This type of sensors is versatile and can be applied across different sectors to monitor liquid levels in tanks, containers, and pipelines. They are highly proficient in industrial manufacturing, chemical processing, water treatment, and wastewater treatment.

- Ultrasonic level sensors operate without making physical contact, removing the necessity to touch the material being gauged. This decreases the chance of contamination and need for maintenance, making them appropriate for hazardous or corrosive materials where contact sensors are not safe. These sensors are highly effective in challenging environments characterized by extreme temperatures, high pressure, dust, vapor, or foam. Their dependability ensures consistent and precise level readings, especially in difficult industrial settings. These sensors are affordable because of their dependability, minimal upkeep, and adaptability.

- Ultrasonic level sensors are suitable for use in deep tanks or containers due to their ability to measure levels over long distances. They precisely detect levels in big storage tanks or open reservoirs, offering real-time data for inventory management and process control. Sectors are incorporating ultrasonic level sensors into IoT and automation systems to enable remote monitoring, data analysis, and predictive maintenance. This integration boosts productivity, minimizes manual involvement, and elevates operational effectiveness.

Level Sensor Market Regional Insights:

North America is Expected to Dominate the Market Over the Forecast Period

- Technological innovation in North America is spearheaded by a strong emphasis on research and development. Numerous leading sensor manufacturers and tech companies are investing in advanced level sensing technologies, promoting their use across various industries and sustaining their market leadership. This region possesses a robust industrial infrastructure in sectors like manufacturing, oil and gas, automotive, and aerospace, resulting in a significant need for level sensing solutions. The established industrial foundation strengthens the region's position as a market leader in level sensors.

- Strict regulations in this region, especially in the healthcare, food and beverage, and environmental protection sectors, necessitate the use of high-quality level sensors to ensure safety and quality standards are met. Corporations prioritize compliance with regulations and allocate resources to develop cutting-edge sensor technologies. The stable economic conditions and favourable investment environment in North America are fuelling growth and innovation in the level sensor market. Substantial investments in research, infrastructure, and industrial growth enable manufacturers to enhance market presence and create customized solutions.

- North American industries are at the forefront in the implementation of industrial automation, Industry 4.0, and smart level sensors to improve real-time monitoring, predictive maintenance, and process optimization. The increasing need for automation technologies, IoT, and data analytics in manufacturing processes is boosting North America's standing in the level sensor market. Top level sensor producers in North America utilize their market dominance, distribution channels, and international presence to boost global sales. A strong brand image and loyalty from customers play a role in North America's leading position in the worldwide level sensor industry.

- From this graph, it is shown that the U.S. level sensor market has witnessed steady growth across various sectors from 2019 to 2023, driven by factors such as industrial automation, technological advancements, and increasing demand for IoT-enabled devices. The market has shown resilience even amidst economic uncertainties, indicating sustained demand for level sensing solutions across diverse industries.

Level Sensor Market Active Players

- Emerson Electric Co. (USA)

- Endress+Hauser AG (Switzerland)

- VEGA Grieshaber KG (Germany)

- Siemens AG (Germany)

- ABB Ltd. (Switzerland)

- Honeywell International Inc. (USA)

- Schneider Electric SE (France)

- AMETEK Inc. (USA)

- Texas Instruments Inc. (USA)

- Fortive Corporation (USA)

- TE Connectivity Ltd. (Switzerland)

- Gems Sensors, Inc. (USA)

- KROHNE Messtechnik GmbH (Germany)

- Pepperl+Fuchs GmbH (Germany)

- SICK AG (Germany)

- First Sensor AG (Germany)

- Murata Manufacturing Co., Ltd. (Japan)

- Yokogawa Electric Corporation (Japan)

- Balluff GmbH (Germany)

- Ifm electronic Gmbh (Germany)

- FMC Technologies, Inc. (USA)

- Other Active Player

|

Global Level Sensor Market |

|||

|

Base Year: |

2024 |

Forecast Period: |

2025-2032 |

|

Historical Data: |

2018 to 2023 |

Market Size in 2024: |

USD 5618.25 Million |

|

Forecast Period 2025-32 CAGR: |

7.99 % |

Market Size in 2032: |

USD 10391.28 Million |

|

Segments Covered: |

By Type |

|

|

|

By Technology |

|

||

|

By Monitoring Type |

|

||

|

By End-User |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

Chapter 1: Introduction

1.1 Scope and Coverage

Chapter 2:Executive Summary

Chapter 3: Market Landscape

3.1 Market Dynamics

3.1.1 Drivers

3.1.2 Restraints

3.1.3 Opportunities

3.1.4 Challenges

3.2 Market Trend Analysis

3.3 PESTLE Analysis

3.4 Porter's Five Forces Analysis

3.5 Industry Value Chain Analysis

3.6 Ecosystem

3.7 Regulatory Landscape

3.8 Price Trend Analysis

3.9 Patent Analysis

3.10 Technology Evolution

3.11 Investment Pockets

3.12 Import-Export Analysis

Chapter 4: Level Sensor Market by Type (2018-2032)

4.1 Level Sensor Market Snapshot and Growth Engine

4.2 Market Overview

4.3 Contact Level Sensors

4.3.1 Introduction and Market Overview

4.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

4.3.3 Key Market Trends, Growth Factors, and Opportunities

4.3.4 Geographic Segmentation Analysis

4.4 Non-Contact Level Sensors

Chapter 5: Level Sensor Market by Technology (2018-2032)

5.1 Level Sensor Market Snapshot and Growth Engine

5.2 Market Overview

5.3 Ultrasonic

5.3.1 Introduction and Market Overview

5.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

5.3.3 Key Market Trends, Growth Factors, and Opportunities

5.3.4 Geographic Segmentation Analysis

5.4 Magneto-strictive

5.5 Hydrostatic

5.6 Optical

5.7 Conductive

5.8 Others {Capacitive

5.9 Laser

5.10 Microwave

5.11 Nuclear}

Chapter 6: Level Sensor Market by Monitoring Type (2018-2032)

6.1 Level Sensor Market Snapshot and Growth Engine

6.2 Market Overview

6.3 Continuous Level Monitoring

6.3.1 Introduction and Market Overview

6.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

6.3.3 Key Market Trends, Growth Factors, and Opportunities

6.3.4 Geographic Segmentation Analysis

6.4 Point Level Monitoring

6.5 Interface Level Sensing

Chapter 7: Level Sensor Market by End-User (2018-2032)

7.1 Level Sensor Market Snapshot and Growth Engine

7.2 Market Overview

7.3 Chemical

7.3.1 Introduction and Market Overview

7.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

7.3.3 Key Market Trends, Growth Factors, and Opportunities

7.3.4 Geographic Segmentation Analysis

7.4 Food and Beverages

7.5 Industrial Manufacturing

7.6 Oil and Gas

7.7 Automotive

7.8 Others {Water and Waste Management

7.9 Household

7.10 Agriculture

7.11 Healthcare}

Chapter 8: Company Profiles and Competitive Analysis

8.1 Competitive Landscape

8.1.1 Competitive Benchmarking

8.1.2 Level Sensor Market Share by Manufacturer (2024)

8.1.3 Industry BCG Matrix

8.1.4 Heat Map Analysis

8.1.5 Mergers and Acquisitions

8.2 EMERSON ELECTRIC CO. (USA)

8.2.1 Company Overview

8.2.2 Key Executives

8.2.3 Company Snapshot

8.2.4 Role of the Company in the Market

8.2.5 Sustainability and Social Responsibility

8.2.6 Operating Business Segments

8.2.7 Product Portfolio

8.2.8 Business Performance

8.2.9 Key Strategic Moves and Recent Developments

8.2.10 SWOT Analysis

8.3 ENDRESS+HAUSER AG (SWITZERLAND)

8.4 VEGA GRIESHABER KG (GERMANY)

8.5 SIEMENS AG (GERMANY)

8.6 ABB LTD. (SWITZERLAND)

8.7 HONEYWELL INTERNATIONAL INC. (USA)

8.8 SCHNEIDER ELECTRIC SE (FRANCE)

8.9 AMETEK INC. (USA)

8.10 TEXAS INSTRUMENTS INC. (USA)

8.11 FORTIVE CORPORATION (USA)

8.12 TE CONNECTIVITY LTD. (SWITZERLAND)

8.13 GEMS SENSORS INC. (USA)

8.14 KROHNE MESSTECHNIK GMBH (GERMANY)

8.15 PEPPERL+FUCHS GMBH (GERMANY)

8.16 SICK AG (GERMANY)

8.17 FIRST SENSOR AG (GERMANY)

8.18 MURATA MANUFACTURING COLTD. (JAPAN)

8.19 YOKOGAWA ELECTRIC CORPORATION (JAPAN)

8.20 BALLUFF GMBH (GERMANY)

8.21 IFM ELECTRONIC GMBH (GERMANY)

8.22 FMC TECHNOLOGIES INC. (USA)

8.23 DWYER INSTRUMENTS INC. (USA)

8.24 MADISON COMPANY (USA)

Chapter 9: Global Level Sensor Market By Region

9.1 Overview

9.2. North America Level Sensor Market

9.2.1 Key Market Trends, Growth Factors and Opportunities

9.2.2 Top Key Companies

9.2.3 Historic and Forecasted Market Size by Segments

9.2.4 Historic and Forecasted Market Size by Type

9.2.4.1 Contact Level Sensors

9.2.4.2 Non-Contact Level Sensors

9.2.5 Historic and Forecasted Market Size by Technology

9.2.5.1 Ultrasonic

9.2.5.2 Magneto-strictive

9.2.5.3 Hydrostatic

9.2.5.4 Optical

9.2.5.5 Conductive

9.2.5.6 Others {Capacitive

9.2.5.7 Laser

9.2.5.8 Microwave

9.2.5.9 Nuclear}

9.2.6 Historic and Forecasted Market Size by Monitoring Type

9.2.6.1 Continuous Level Monitoring

9.2.6.2 Point Level Monitoring

9.2.6.3 Interface Level Sensing

9.2.7 Historic and Forecasted Market Size by End-User

9.2.7.1 Chemical

9.2.7.2 Food and Beverages

9.2.7.3 Industrial Manufacturing

9.2.7.4 Oil and Gas

9.2.7.5 Automotive

9.2.7.6 Others {Water and Waste Management

9.2.7.7 Household

9.2.7.8 Agriculture

9.2.7.9 Healthcare}

9.2.8 Historic and Forecast Market Size by Country

9.2.8.1 US

9.2.8.2 Canada

9.2.8.3 Mexico

9.3. Eastern Europe Level Sensor Market

9.3.1 Key Market Trends, Growth Factors and Opportunities

9.3.2 Top Key Companies

9.3.3 Historic and Forecasted Market Size by Segments

9.3.4 Historic and Forecasted Market Size by Type

9.3.4.1 Contact Level Sensors

9.3.4.2 Non-Contact Level Sensors

9.3.5 Historic and Forecasted Market Size by Technology

9.3.5.1 Ultrasonic

9.3.5.2 Magneto-strictive

9.3.5.3 Hydrostatic

9.3.5.4 Optical

9.3.5.5 Conductive

9.3.5.6 Others {Capacitive

9.3.5.7 Laser

9.3.5.8 Microwave

9.3.5.9 Nuclear}

9.3.6 Historic and Forecasted Market Size by Monitoring Type

9.3.6.1 Continuous Level Monitoring

9.3.6.2 Point Level Monitoring

9.3.6.3 Interface Level Sensing

9.3.7 Historic and Forecasted Market Size by End-User

9.3.7.1 Chemical

9.3.7.2 Food and Beverages

9.3.7.3 Industrial Manufacturing

9.3.7.4 Oil and Gas

9.3.7.5 Automotive

9.3.7.6 Others {Water and Waste Management

9.3.7.7 Household

9.3.7.8 Agriculture

9.3.7.9 Healthcare}

9.3.8 Historic and Forecast Market Size by Country

9.3.8.1 Russia

9.3.8.2 Bulgaria

9.3.8.3 The Czech Republic

9.3.8.4 Hungary

9.3.8.5 Poland

9.3.8.6 Romania

9.3.8.7 Rest of Eastern Europe

9.4. Western Europe Level Sensor Market

9.4.1 Key Market Trends, Growth Factors and Opportunities

9.4.2 Top Key Companies

9.4.3 Historic and Forecasted Market Size by Segments

9.4.4 Historic and Forecasted Market Size by Type

9.4.4.1 Contact Level Sensors

9.4.4.2 Non-Contact Level Sensors

9.4.5 Historic and Forecasted Market Size by Technology

9.4.5.1 Ultrasonic

9.4.5.2 Magneto-strictive

9.4.5.3 Hydrostatic

9.4.5.4 Optical

9.4.5.5 Conductive

9.4.5.6 Others {Capacitive

9.4.5.7 Laser

9.4.5.8 Microwave

9.4.5.9 Nuclear}

9.4.6 Historic and Forecasted Market Size by Monitoring Type

9.4.6.1 Continuous Level Monitoring

9.4.6.2 Point Level Monitoring

9.4.6.3 Interface Level Sensing

9.4.7 Historic and Forecasted Market Size by End-User

9.4.7.1 Chemical

9.4.7.2 Food and Beverages

9.4.7.3 Industrial Manufacturing

9.4.7.4 Oil and Gas

9.4.7.5 Automotive

9.4.7.6 Others {Water and Waste Management

9.4.7.7 Household

9.4.7.8 Agriculture

9.4.7.9 Healthcare}

9.4.8 Historic and Forecast Market Size by Country

9.4.8.1 Germany

9.4.8.2 UK

9.4.8.3 France

9.4.8.4 The Netherlands

9.4.8.5 Italy

9.4.8.6 Spain

9.4.8.7 Rest of Western Europe

9.5. Asia Pacific Level Sensor Market

9.5.1 Key Market Trends, Growth Factors and Opportunities

9.5.2 Top Key Companies

9.5.3 Historic and Forecasted Market Size by Segments

9.5.4 Historic and Forecasted Market Size by Type

9.5.4.1 Contact Level Sensors

9.5.4.2 Non-Contact Level Sensors

9.5.5 Historic and Forecasted Market Size by Technology

9.5.5.1 Ultrasonic

9.5.5.2 Magneto-strictive

9.5.5.3 Hydrostatic

9.5.5.4 Optical

9.5.5.5 Conductive

9.5.5.6 Others {Capacitive

9.5.5.7 Laser

9.5.5.8 Microwave

9.5.5.9 Nuclear}

9.5.6 Historic and Forecasted Market Size by Monitoring Type

9.5.6.1 Continuous Level Monitoring

9.5.6.2 Point Level Monitoring

9.5.6.3 Interface Level Sensing

9.5.7 Historic and Forecasted Market Size by End-User

9.5.7.1 Chemical

9.5.7.2 Food and Beverages

9.5.7.3 Industrial Manufacturing

9.5.7.4 Oil and Gas

9.5.7.5 Automotive

9.5.7.6 Others {Water and Waste Management

9.5.7.7 Household

9.5.7.8 Agriculture

9.5.7.9 Healthcare}

9.5.8 Historic and Forecast Market Size by Country

9.5.8.1 China

9.5.8.2 India

9.5.8.3 Japan

9.5.8.4 South Korea

9.5.8.5 Malaysia

9.5.8.6 Thailand

9.5.8.7 Vietnam

9.5.8.8 The Philippines

9.5.8.9 Australia

9.5.8.10 New Zealand

9.5.8.11 Rest of APAC

9.6. Middle East & Africa Level Sensor Market

9.6.1 Key Market Trends, Growth Factors and Opportunities

9.6.2 Top Key Companies

9.6.3 Historic and Forecasted Market Size by Segments

9.6.4 Historic and Forecasted Market Size by Type

9.6.4.1 Contact Level Sensors

9.6.4.2 Non-Contact Level Sensors

9.6.5 Historic and Forecasted Market Size by Technology

9.6.5.1 Ultrasonic

9.6.5.2 Magneto-strictive

9.6.5.3 Hydrostatic

9.6.5.4 Optical

9.6.5.5 Conductive

9.6.5.6 Others {Capacitive

9.6.5.7 Laser

9.6.5.8 Microwave

9.6.5.9 Nuclear}

9.6.6 Historic and Forecasted Market Size by Monitoring Type

9.6.6.1 Continuous Level Monitoring

9.6.6.2 Point Level Monitoring

9.6.6.3 Interface Level Sensing

9.6.7 Historic and Forecasted Market Size by End-User

9.6.7.1 Chemical

9.6.7.2 Food and Beverages

9.6.7.3 Industrial Manufacturing

9.6.7.4 Oil and Gas

9.6.7.5 Automotive

9.6.7.6 Others {Water and Waste Management

9.6.7.7 Household

9.6.7.8 Agriculture

9.6.7.9 Healthcare}

9.6.8 Historic and Forecast Market Size by Country

9.6.8.1 Turkiye

9.6.8.2 Bahrain

9.6.8.3 Kuwait

9.6.8.4 Saudi Arabia

9.6.8.5 Qatar

9.6.8.6 UAE

9.6.8.7 Israel

9.6.8.8 South Africa

9.7. South America Level Sensor Market

9.7.1 Key Market Trends, Growth Factors and Opportunities

9.7.2 Top Key Companies

9.7.3 Historic and Forecasted Market Size by Segments

9.7.4 Historic and Forecasted Market Size by Type

9.7.4.1 Contact Level Sensors

9.7.4.2 Non-Contact Level Sensors

9.7.5 Historic and Forecasted Market Size by Technology

9.7.5.1 Ultrasonic

9.7.5.2 Magneto-strictive

9.7.5.3 Hydrostatic

9.7.5.4 Optical

9.7.5.5 Conductive

9.7.5.6 Others {Capacitive

9.7.5.7 Laser

9.7.5.8 Microwave

9.7.5.9 Nuclear}

9.7.6 Historic and Forecasted Market Size by Monitoring Type

9.7.6.1 Continuous Level Monitoring

9.7.6.2 Point Level Monitoring

9.7.6.3 Interface Level Sensing

9.7.7 Historic and Forecasted Market Size by End-User

9.7.7.1 Chemical

9.7.7.2 Food and Beverages

9.7.7.3 Industrial Manufacturing

9.7.7.4 Oil and Gas

9.7.7.5 Automotive

9.7.7.6 Others {Water and Waste Management

9.7.7.7 Household

9.7.7.8 Agriculture

9.7.7.9 Healthcare}

9.7.8 Historic and Forecast Market Size by Country

9.7.8.1 Brazil

9.7.8.2 Argentina

9.7.8.3 Rest of SA

Chapter 10 Analyst Viewpoint and Conclusion

10.1 Recommendations and Concluding Analysis

10.2 Potential Market Strategies

Chapter 11 Research Methodology

11.1 Research Process

11.2 Primary Research

11.3 Secondary Research

|

Global Level Sensor Market |

|||

|

Base Year: |

2024 |

Forecast Period: |

2025-2032 |

|

Historical Data: |

2018 to 2023 |

Market Size in 2024: |

USD 5618.25 Million |

|

Forecast Period 2025-32 CAGR: |

7.99 % |

Market Size in 2032: |

USD 10391.28 Million |

|

Segments Covered: |

By Type |

|

|

|

By Technology |

|

||

|

By Monitoring Type |

|

||

|

By End-User |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||