Industry 4.0 Market Synopsis

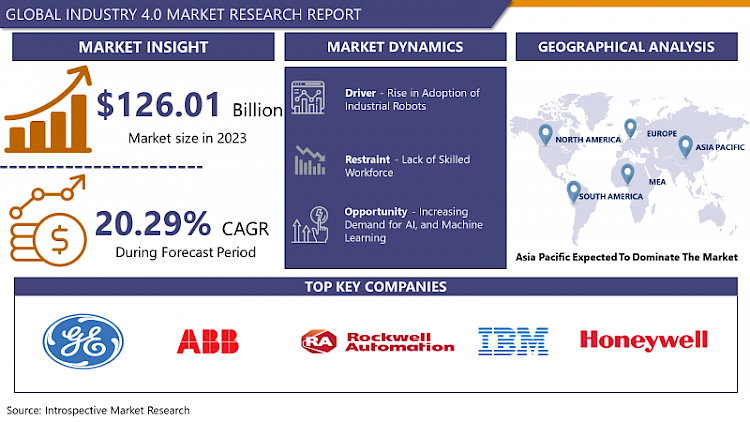

Industry 4.0 Market Size Was Valued at USD 126.01 Billion in 2023, and is Projected to Reach USD 664.46 Billion by 2032, Growing at a CAGR of 20.29% From 2024-2032

Industry 4.0 marks a transformative era in the business landscape, reshaping how products are created, refined, and distributed. This paradigm shift involves the integration of cutting-edge technologies like the Internet of Things (IoT), cloud computing, artificial intelligence (AI), and machine learning into manufacturing processes.

- As businesses embrace these innovations, they move towards establishing smart factories that leverage advanced sensors, embedded software, and robotics to collect and analyze data. The convergence of manufacturing data with information from ERP, supply chain, and customer service systems opens up new vistas of visibility and insight, breaking down silos that previously separated crucial operational information.

- Manufacturers are at the forefront of incorporating Industry 4.0 technologies into their production facilities. Smart factories, powered by IoT devices, cloud computing, and AI, enable sophisticated data collection and analysis. These digital technologies pave the way for increased automation, predictive maintenance, and self-optimization of processes. The result is a level of efficiency and responsiveness that was previously unattainable.

- A hallmark of Industry 4.0 is the synergy between manufacturing data and operational data from diverse corporate systems. The amalgamation of these datasets provides real-time visibility into production assets. Advanced analytics, fueled by massive amounts of big data from plant sensors, enables predictive maintenance strategies to reduce downtime. This data-driven approach empowers manufacturers to make informed decisions, optimize processes, and respond swiftly to consumer needs.

Industry 4.0 Market Trend Analysis

Rise in Adoption of Industrial Robots

- Industrial robots, equipped with advanced sensors and programming, can perform tasks with a level of accuracy and consistency that is often challenging for human workers. This leads to a reduction in errors and variability in production, resulting in higher-quality outputs. The automation of routine and repetitive tasks by robots also allows human workers to focus on more complex and creative aspects of their jobs, fostering a synergistic collaboration between humans and machines.

- Industry 4.0 envisions the creation of smart factories where interconnected devices and systems can adapt to changing demands and production requirements. Industrial robots play a crucial role in achieving this flexibility by easily adapting to different tasks and processes through reprogramming or reconfiguration. This scalability enables businesses to respond quickly to market fluctuations, customize production according to varying demands, and streamline processes for improved overall efficiency.

Increasing Demand for AI, and Machine Learning.

- AI and ML algorithms can analyze vast amounts of data generated by smart factories, identifying patterns and trends that may not be apparent through traditional analysis. This capability empowers manufacturers to make data-driven decisions in real-time, optimizing production processes, predicting equipment failures before they occur, and ultimately enhancing overall operational efficiency. As Industry 4.0 relies heavily on data integration and analytics, the demand for AI and ML technologies aligns to create intelligent, self-optimizing manufacturing systems.

- The growing popularity of AI and machine learning also opens doors to increased personalization and customization in manufacturing processes, representing a valuable opportunity within the Industry 4.0 landscape. These technologies enable manufacturers to gather and analyze customer data, preferences, and market trends, facilitating the production of highly customized products at scale. Whether it's adapting production lines to changing consumer demands or tailoring products to individual specifications, AI and ML contribute to a more flexible and responsive manufacturing environment.

Industry 4.0 Market Segment Analysis:

Industry 4.0 Market Segmented on the basis of Technologies, Applications, and Industry.

By Technologies, Industrial Robots segment is expected to dominate the market during the forecast period

- Industrial robots are poised to dominate the technology landscape within Industry 4.0 due to their unparalleled precision and efficiency in manufacturing processes. These robots can execute repetitive and complex tasks with a level of accuracy that is challenging for human workers to match. As businesses increasingly seek to optimize production and minimize errors, the integration of industrial robots becomes imperative. Their ability to operate continuously, without the need for breaks, and to handle intricate tasks with consistency positions them as a cornerstone technology for achieving higher levels of efficiency in smart factories.

- In automotive assembly lines, electronics manufacturing, or intricate tasks in aerospace, industrial robots can be programmed and configured to perform a wide range of functions. This versatility aligns with the principles of Industry 4.0, where interconnected and flexible technologies are essential. As smart factories evolve to meet changing market demands and customization requirements, industrial robots stand out for their ability to seamlessly integrate into different production environments.

By Industry, Manufacturing segment held the largest share of 38.6% in 2022

- Industry 4.0 technologies offered within manufacturing environments. Smart factories equipped with Industrial IoT, artificial intelligence, machine learning, and automation technologies allow manufacturers to streamline and enhance every stage of the production process. From predictive maintenance to real-time monitoring of equipment and inventory, Industry 4.0 solutions empower manufacturing industries to achieve unprecedented levels of efficiency and productivity. This heightened efficiency not only results in cost savings but also positions manufacturing at the forefront of realizing the transformative potential of Industry 4.0.

- Manufacturing's lead in the adoption of Industry 4.0 is also driven by the sector's inherent need for flexibility and customization. Industry 4.0 technologies enable manufacturers to pivot quickly in response to market trends and changing consumer demands. Smart manufacturing systems, facilitated by technologies like digital twins and industrial robots, allow for agile production processes that can be easily reconfigured to accommodate varying product specifications. As customization becomes a key differentiator in the competitive landscape, the manufacturing industry leverages Industry 4.0 to meet these demands effectively.

Industry 4.0 Market Regional Insights:

Asia Pacific is Expected to Dominate the Market Over the Forecast period

- China's economic prowess and a robust industrial sector drive demand for advanced technologies like the Industrial Internet of Things (IIOTs) and digital twins, supporting Industry 4.0 market growth. The expansion of the Small and Medium-sized Businesses (SMBs) sector contributes to China's economic growth, creating an increased requirement for Industry 4.0 technologies to bolster SMBs through the application of advanced technologies.

- India's industrial development thrives on a growing economy and a sizable youth population. The Government of India's emphasis on boosting manufacturing facilities aligns with employment generation goals. The adoption of Industry 4.0 in India is anticipated to surge as advanced systems and technologies enhance efficiency and productivity in the country's manufacturing sector.

- Positioned as an automated industrial economy, Japan leads in Asia-Pacific's Industry 4.0 evolution with its Industrial version 4.0 strategies. Renowned as a manufacturing hub for factory automation products, Japan plays a pivotal role in supplying these innovations to other markets in the Asia-Pacific region.

Industry 4.0 Market Top Key Players:

- General Electric (USA)

- ABB (Switzerland)

- Rockwell Automation (USA)

- IBM (USA)

- PTC (USA)

- Honeywell (USA)

- Johnson Controls International plc(USA)

- Siemens (Germany)

- Bosch Rexroth (Germany)

- Schneider Electric (France)

- Fanuc Corporation (Japan)

- Toshiba Corporation (Japan)

- Yaskawa Electric Corporation (Japan)

- Mindray Medical International Limited (China)

- Haier Group Corporation (China)

- Huawei Technologies Co., Ltd. (China)

- BYD Company Limited (China)

- Tata Consultancy Services (TCS)(India)

- Infosys (India)

- Mahindra & Mahindra (India)

- Foxconn Technology Group (Taiwan)

- Samsung Electronics (South Korea)

- Lenovo Group (Hong Kong)

- ASE Technology Holding Co., Ltd. (Taiwan)

- Hitachi, Ltd. (Japan)

- Advantech Co., Ltd. (Taiwan)

Key Industry Developments in the Industry 4.0 Market:

- In June 2023, GE HealthCare introduced Sonic DL, a state-of-the-art AI Deep Learning (DL) technology that has received FDA clearance. This cutting-edge technology excels in acquiring high-quality magnetic resonance (MR) images at a remarkable pace—up to 12 times faster than conventional methods. This accelerated imaging capability is especially notable for cardiac imaging, enabling comprehensive scans within a single heartbeat.

- In February 2023, Johnson Controls International and Willow, a digital twin solutions provider for critical infrastructure and real estate, joined forces in a global collaboration aimed at the digital transformation of buildings and facilities. This strategic partnership underscores the commitment of both Johnsons Controls and Willow to deliver cutting-edge solutions to their customers. The increasing significance of digital twins in the design, construction, and maintenance of buildings and facilities is highlighted. These digital replicas play a crucial role in handling extensive datasets and forecasting patterns and trends, contributing to the creation and upkeep of healthier built environments.

|

Global Industry 4.0 Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 126.01 Bn. |

|

Forecast Period 2024-32 CAGR: |

20.29% |

Market Size in 2032: |

USD 664.46 Bn. |

|

Segments Covered: |

By Technologies |

|

|

|

By Application |

|

||

|

By Industry |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

- INTRODUCTION

- RESEARCH OBJECTIVES

- RESEARCH METHODOLOGY

- RESEARCH PROCESS

- SCOPE AND COVERAGE

- Market Definition

- Key Questions Answered

- MARKET SEGMENTATION

- EXECUTIVE SUMMARY

- MARKET OVERVIEW

- GROWTH OPPORTUNITIES BY SEGMENT

- MARKET LANDSCAPE

- PORTER’S FIVE FORCES ANALYSIS

- Bargaining Power Of Supplier

- Threat Of New Entrants

- Threat Of Substitutes

- Competitive Rivalry

- Bargaining Power Among Buyers

- INDUSTRY VALUE CHAIN ANALYSIS

- MARKET DYNAMICS

- Drivers

- Restraints

- Opportunities

- Challenges

- MARKET TREND ANALYSIS

- REGULATORY LANDSCAPE

- PESTLE ANALYSIS

- PRICE TREND ANALYSIS

- PATENT ANALYSIS

- TECHNOLOGY EVALUATION

- MARKET IMPACT OF THE RUSSIA-UKRAINE WAR

- Geopolitical Market Disruptions

- Supply Chain Disruptions

- Instability in Emerging Markets

- ECOSYSTEM

- PORTER’S FIVE FORCES ANALYSIS

- Industry 4.0 MARKET BY TECHNOLOGIES (2016-2030)

- Industry 4.0 MARKET SNAPSHOT AND GROWTH ENGINE

- MARKET OVERVIEW

- INDUSTRIAL ROBOTS

- Introduction And Market Overview

- Historic And Forecasted Market Size in Value (2016 – 2030F)

- Historic And Forecasted Market Size in Volume (2016 – 2030F)

- Key Market Trends, Growth Factors And Opportunities

- Geographic Segmentation Analysis

- AI IN MANUFACTURING

- DIGITAL TWIN

- MACHINE VISION

- INDUSTRIAL SENSORS

- BLOCKCHAIN

- MACHINE CONDITION MONITORING

- INDUSTRIAL 3D PRINTING

- HMI (HUMAN-MACHINE INTERFACE)

- AGVS (AUTOMATED GUIDED VEHICLES)

- Industry 4.0 MARKET BY APPLICATIONS (2016-2030)

- Industry 4.0 MARKET SNAPSHOT AND GROWTH ENGINE

- MARKET OVERVIEW

- SMART FACTORY

- Introduction And Market Overview

- Historic And Forecasted Market Size in Value (2016 – 2030F)

- Historic And Forecasted Market Size in Volume (2016 – 2030F)

- Key Market Trends, Growth Factors And Opportunities

- Geographic Segmentation Analysis

- INDUSTRIAL AUTOMATION

- INDUSTRIAL IOT (INTERNET OF THINGS)

- Industry 4.0 MARKET BY INDUSTRY (2016-2030)

- Industry 4.0 MARKET SNAPSHOT AND GROWTH ENGINE

- MARKET OVERVIEW

- MANUFACTURING

- Introduction And Market Overview

- Historic And Forecasted Market Size in Value (2016 – 2030F)

- Historic And Forecasted Market Size in Volume (2016 – 2030F)

- Key Market Trends, Growth Factors And Opportunities

- Geographic Segmentation Analysis

- AEROSPACE AND DEFENSE

- AUTOMOTIVE

- OIL AND GAS

- ENERGY & UTILITIES

- ELECTRONICS AND CONSUMER GOODS

- OTHERS

- COMPANY PROFILES AND COMPETITIVE ANALYSIS

- COMPETITIVE LANDSCAPE

- Competitive Positioning

- Industry 4.0 Market Share By Manufacturer (2022)

- Industry BCG Matrix

- Heat Map Analysis

- Mergers & Acquisitions

- GENERAL ELECTRIC

- Company Overview

- Key Executives

- Company Snapshot

- Role of the Company in the Market

- Sustainability and Social Responsibility

- Operating Business Segments

- Product Portfolio

- Business Performance (Production Volume, Sales Volume, Sales Margin, Production Capacity, Capacity Utilization Rate)

- Key Strategic Moves And Recent Developments

- SWOT Analysis

- ABB

- ROCKWELL AUTOMATION

- IBM

- PTC

- HONEYWELL

- JOHNSON CONTROLS INTERNATIONAL PLC

- SIEMENS

- BOSCH REXROTH

- SCHNEIDER ELECTRIC

- FANUC CORPORATION

- TOSHIBA CORPORATION

- YASKAWA ELECTRIC CORPORATION

- MINDRAY MEDICAL INTERNATIONAL LIMITED

- HAIER GROUP CORPORATION

- HUAWEI TECHNOLOGIES CO., LTD.

- BYD COMPANY LIMITED

- TATA CONSULTANCY SERVICES (TCS)

- INFOSYS

- MAHINDRA & MAHINDRA

- FOXCONN TECHNOLOGY GROUP

- SAMSUNG ELECTRONICS

- LENOVO GROUP

- ASE TECHNOLOGY HOLDING CO., LTD.

- HITACHI, LTD.

- ADVANTECH CO., LTD.

- COMPETITIVE LANDSCAPE

- GLOBAL Industry 4.0 MARKET BY REGION

- OVERVIEW

- NORTH AMERICA

- Key Market Trends, Growth Factors And Opportunities

- Key Manufacturers

- Historic And Forecasted Market Size By TECHNOLOGIES

- Historic And Forecasted Market Size By APPLICATIONS

- Historic And Forecasted Market Size By INDUSTRY

- Historic And Forecasted Market Size By Country

- USA

- Canada

- Mexico

- EASTERN EUROPE

- Key Market Trends, Growth Factors And Opportunities

- Key Manufacturers

- Historic And Forecasted Market Size By Segments

- Historic And Forecasted Market Size By Country

- Russia

- Bulgaria

- The Czech Republic

- Hungary

- Poland

- Romania

- Rest Of Eastern Europe

- WESTERN EUROPE

- Key Market Trends, Growth Factors And Opportunities

- Key Manufacturers

- Historic And Forecasted Market Size By Segments

- Historic And Forecasted Market Size By Country

- Germany

- United Kingdom

- France

- The Netherlands

- Italy

- Spain

- Rest Of Western Europe

- ASIA PACIFIC

- Key Market Trends, Growth Factors And Opportunities

- Key Manufacturers

- Historic And Forecasted Market Size By Segments

- Historic And Forecasted Market Size By Country

- China

- India

- Japan

- South Korea

- Malaysia

- Thailand

- Vietnam

- The Philippines

- Australia

- New-Zealand

- Rest Of APAC

- MIDDLE EAST & AFRICA

- Key Market Trends, Growth Factors And Opportunities

- Key Manufacturers

- Historic And Forecasted Market Size By Segments

- Historic And Forecasted Market Size By Country

- Turkey

- Bahrain

- Kuwait

- Saudi Arabia

- Qatar

- UAE

- Israel

- South Africa

- SOUTH AMERICA

- Key Market Trends, Growth Factors And Opportunities

- Key Manufacturers

- Historic And Forecasted Market Size By Segments

- Historic And Forecasted Market Size By Country

- Brazil

- Argentina

- Rest of South America

- INVESTMENT ANALYSIS

- ANALYST VIEWPOINT AND CONCLUSION

- Recommendations and Concluding Analysis

- Potential Market Strategies

|

Global Industry 4.0 Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 126.01 Bn. |

|

Forecast Period 2024-32 CAGR: |

20.29% |

Market Size in 2032: |

USD 664.46 Bn. |

|

Segments Covered: |

By Technologies |

|

|

|

By Application |

|

||

|

By Industry |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

LIST OF TABLES

TABLE 001. EXECUTIVE SUMMARY

TABLE 002. INDUSTRY 4.0 MARKET BARGAINING POWER OF SUPPLIERS

TABLE 003. INDUSTRY 4.0 MARKET BARGAINING POWER OF CUSTOMERS

TABLE 004. INDUSTRY 4.0 MARKET COMPETITIVE RIVALRY

TABLE 005. INDUSTRY 4.0 MARKET THREAT OF NEW ENTRANTS

TABLE 006. INDUSTRY 4.0 MARKET THREAT OF SUBSTITUTES

TABLE 007. INDUSTRY 4.0 MARKET BY TECHNOLOGY

TABLE 008. INDUSTRIAL ROBOTS MARKET OVERVIEW (2016-2028)

TABLE 009. AI IN MANUFACTURING MARKET OVERVIEW (2016-2028)

TABLE 010. DIGITAL TWIN MARKET OVERVIEW (2016-2028)

TABLE 011. MACHINE VISION MARKET OVERVIEW (2016-2028)

TABLE 012. INDUSTRIAL SENSORS MARKET OVERVIEW (2016-2028)

TABLE 013. BLOCKCHAIN MARKET OVERVIEW (2016-2028)

TABLE 014. MACHINE CONDITION MONITORING MARKET OVERVIEW (2016-2028)

TABLE 015. INDUSTRIAL 3D PRINTING MARKET OVERVIEW (2016-2028)

TABLE 016. HMI MARKET OVERVIEW (2016-2028)

TABLE 017. AGV'S MARKET OVERVIEW (2016-2028)

TABLE 018. INDUSTRY 4.0 MARKET BY APPLICATION

TABLE 019. SMART FACTORY MARKET OVERVIEW (2016-2028)

TABLE 020. INDUSTRIAL AUTOMATION MARKET OVERVIEW (2016-2028)

TABLE 021. INDUSTRIAL IOT MARKET OVERVIEW (2016-2028)

TABLE 022. INDUSTRY 4.0 MARKET BY VERTICAL

TABLE 023. MANUFACTURING MARKET OVERVIEW (2016-2028)

TABLE 024. AEROSPACE AND DEFENSE MARKET OVERVIEW (2016-2028)

TABLE 025. AUTOMOTIVE MARKET OVERVIEW (2016-2028)

TABLE 026. OIL AND GAS MARKET OVERVIEW (2016-2028)

TABLE 027. ENERGY & UTILITIES MARKET OVERVIEW (2016-2028)

TABLE 028. ELECTRONICS AND CONSUMER GOODS MARKET OVERVIEW (2016-2028)

TABLE 029. OTHERS MARKET OVERVIEW (2016-2028)

TABLE 030. NORTH AMERICA INDUSTRY 4.0 MARKET, BY TECHNOLOGY (2016-2028)

TABLE 031. NORTH AMERICA INDUSTRY 4.0 MARKET, BY APPLICATION (2016-2028)

TABLE 032. NORTH AMERICA INDUSTRY 4.0 MARKET, BY VERTICAL (2016-2028)

TABLE 033. N INDUSTRY 4.0 MARKET, BY COUNTRY (2016-2028)

TABLE 034. EUROPE INDUSTRY 4.0 MARKET, BY TECHNOLOGY (2016-2028)

TABLE 035. EUROPE INDUSTRY 4.0 MARKET, BY APPLICATION (2016-2028)

TABLE 036. EUROPE INDUSTRY 4.0 MARKET, BY VERTICAL (2016-2028)

TABLE 037. INDUSTRY 4.0 MARKET, BY COUNTRY (2016-2028)

TABLE 038. ASIA PACIFIC INDUSTRY 4.0 MARKET, BY TECHNOLOGY (2016-2028)

TABLE 039. ASIA PACIFIC INDUSTRY 4.0 MARKET, BY APPLICATION (2016-2028)

TABLE 040. ASIA PACIFIC INDUSTRY 4.0 MARKET, BY VERTICAL (2016-2028)

TABLE 041. INDUSTRY 4.0 MARKET, BY COUNTRY (2016-2028)

TABLE 042. MIDDLE EAST & AFRICA INDUSTRY 4.0 MARKET, BY TECHNOLOGY (2016-2028)

TABLE 043. MIDDLE EAST & AFRICA INDUSTRY 4.0 MARKET, BY APPLICATION (2016-2028)

TABLE 044. MIDDLE EAST & AFRICA INDUSTRY 4.0 MARKET, BY VERTICAL (2016-2028)

TABLE 045. INDUSTRY 4.0 MARKET, BY COUNTRY (2016-2028)

TABLE 046. SOUTH AMERICA INDUSTRY 4.0 MARKET, BY TECHNOLOGY (2016-2028)

TABLE 047. SOUTH AMERICA INDUSTRY 4.0 MARKET, BY APPLICATION (2016-2028)

TABLE 048. SOUTH AMERICA INDUSTRY 4.0 MARKET, BY VERTICAL (2016-2028)

TABLE 049. INDUSTRY 4.0 MARKET, BY COUNTRY (2016-2028)

TABLE 050. GENERAL ELECTRIC: SNAPSHOT

TABLE 051. GENERAL ELECTRIC: BUSINESS PERFORMANCE

TABLE 052. GENERAL ELECTRIC: PRODUCT PORTFOLIO

TABLE 053. GENERAL ELECTRIC: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 053. IBM: SNAPSHOT

TABLE 054. IBM: BUSINESS PERFORMANCE

TABLE 055. IBM: PRODUCT PORTFOLIO

TABLE 056. IBM: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 056. SIEMENS: SNAPSHOT

TABLE 057. SIEMENS: BUSINESS PERFORMANCE

TABLE 058. SIEMENS: PRODUCT PORTFOLIO

TABLE 059. SIEMENS: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 059. ABB: SNAPSHOT

TABLE 060. ABB: BUSINESS PERFORMANCE

TABLE 061. ABB: PRODUCT PORTFOLIO

TABLE 062. ABB: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 062. EMERSON ELECTRIC: SNAPSHOT

TABLE 063. EMERSON ELECTRIC: BUSINESS PERFORMANCE

TABLE 064. EMERSON ELECTRIC: PRODUCT PORTFOLIO

TABLE 065. EMERSON ELECTRIC: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 065. HONEYWELL INTERNATIONAL: SNAPSHOT

TABLE 066. HONEYWELL INTERNATIONAL: BUSINESS PERFORMANCE

TABLE 067. HONEYWELL INTERNATIONAL: PRODUCT PORTFOLIO

TABLE 068. HONEYWELL INTERNATIONAL: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 068. ADVANTECH: SNAPSHOT

TABLE 069. ADVANTECH: BUSINESS PERFORMANCE

TABLE 070. ADVANTECH: PRODUCT PORTFOLIO

TABLE 071. ADVANTECH: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 071. BASLER: SNAPSHOT

TABLE 072. BASLER: BUSINESS PERFORMANCE

TABLE 073. BASLER: PRODUCT PORTFOLIO

TABLE 074. BASLER: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 074. CISCO SYSTEMS: SNAPSHOT

TABLE 075. CISCO SYSTEMS: BUSINESS PERFORMANCE

TABLE 076. CISCO SYSTEMS: PRODUCT PORTFOLIO

TABLE 077. CISCO SYSTEMS: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 077. 3D SYSTEMS: SNAPSHOT

TABLE 078. 3D SYSTEMS: BUSINESS PERFORMANCE

TABLE 079. 3D SYSTEMS: PRODUCT PORTFOLIO

TABLE 080. 3D SYSTEMS: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 080. TECHMAN ROBOT: SNAPSHOT

TABLE 081. TECHMAN ROBOT: BUSINESS PERFORMANCE

TABLE 082. TECHMAN ROBOT: PRODUCT PORTFOLIO

TABLE 083. TECHMAN ROBOT: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 083. AIBRAIN: SNAPSHOT

TABLE 084. AIBRAIN: BUSINESS PERFORMANCE

TABLE 085. AIBRAIN: PRODUCT PORTFOLIO

TABLE 086. AIBRAIN: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 086. ADDVERB TECHNOLOGIES: SNAPSHOT

TABLE 087. ADDVERB TECHNOLOGIES: BUSINESS PERFORMANCE

TABLE 088. ADDVERB TECHNOLOGIES: PRODUCT PORTFOLIO

TABLE 089. ADDVERB TECHNOLOGIES: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 089. COGNEX CORPORATION: SNAPSHOT

TABLE 090. COGNEX CORPORATION: BUSINESS PERFORMANCE

TABLE 091. COGNEX CORPORATION: PRODUCT PORTFOLIO

TABLE 092. COGNEX CORPORATION: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 092. INTEL: SNAPSHOT

TABLE 093. INTEL: BUSINESS PERFORMANCE

TABLE 094. INTEL: PRODUCT PORTFOLIO

TABLE 095. INTEL: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 095. JOHN BEAN TECHNOLOGIES CORPORATION: SNAPSHOT

TABLE 096. JOHN BEAN TECHNOLOGIES CORPORATION: BUSINESS PERFORMANCE

TABLE 097. JOHN BEAN TECHNOLOGIES CORPORATION: PRODUCT PORTFOLIO

TABLE 098. JOHN BEAN TECHNOLOGIES CORPORATION: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 098. NVIDIA: SNAPSHOT

TABLE 099. NVIDIA: BUSINESS PERFORMANCE

TABLE 100. NVIDIA: PRODUCT PORTFOLIO

TABLE 101. NVIDIA: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 101. STRATASYS: SNAPSHOT

TABLE 102. STRATASYS: BUSINESS PERFORMANCE

TABLE 103. STRATASYS: PRODUCT PORTFOLIO

TABLE 104. STRATASYS: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 104. DAIFUKU: SNAPSHOT

TABLE 105. DAIFUKU: BUSINESS PERFORMANCE

TABLE 106. DAIFUKU: PRODUCT PORTFOLIO

TABLE 107. DAIFUKU: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 107. UNIVERSAL ROBOTS: SNAPSHOT

TABLE 108. UNIVERSAL ROBOTS: BUSINESS PERFORMANCE

TABLE 109. UNIVERSAL ROBOTS: PRODUCT PORTFOLIO

TABLE 110. UNIVERSAL ROBOTS: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 110. ALGOLUX: SNAPSHOT

TABLE 111. ALGOLUX: BUSINESS PERFORMANCE

TABLE 112. ALGOLUX: PRODUCT PORTFOLIO

TABLE 113. ALGOLUX: KEY STRATEGIC MOVES AND DEVELOPMENTS

LIST OF FIGURES

FIGURE 001. YEARS CONSIDERED FOR ANALYSIS

FIGURE 002. SCOPE OF THE STUDY

FIGURE 003. INDUSTRY 4.0 MARKET OVERVIEW BY REGIONS

FIGURE 004. PORTER'S FIVE FORCES ANALYSIS

FIGURE 005. BARGAINING POWER OF SUPPLIERS

FIGURE 006. COMPETITIVE RIVALRYFIGURE 007. THREAT OF NEW ENTRANTS

FIGURE 008. THREAT OF SUBSTITUTES

FIGURE 009. VALUE CHAIN ANALYSIS

FIGURE 010. PESTLE ANALYSIS

FIGURE 011. INDUSTRY 4.0 MARKET OVERVIEW BY TECHNOLOGY

FIGURE 012. INDUSTRIAL ROBOTS MARKET OVERVIEW (2016-2028)

FIGURE 013. AI IN MANUFACTURING MARKET OVERVIEW (2016-2028)

FIGURE 014. DIGITAL TWIN MARKET OVERVIEW (2016-2028)

FIGURE 015. MACHINE VISION MARKET OVERVIEW (2016-2028)

FIGURE 016. INDUSTRIAL SENSORS MARKET OVERVIEW (2016-2028)

FIGURE 017. BLOCKCHAIN MARKET OVERVIEW (2016-2028)

FIGURE 018. MACHINE CONDITION MONITORING MARKET OVERVIEW (2016-2028)

FIGURE 019. INDUSTRIAL 3D PRINTING MARKET OVERVIEW (2016-2028)

FIGURE 020. HMI MARKET OVERVIEW (2016-2028)

FIGURE 021. AGV'S MARKET OVERVIEW (2016-2028)

FIGURE 022. INDUSTRY 4.0 MARKET OVERVIEW BY APPLICATION

FIGURE 023. SMART FACTORY MARKET OVERVIEW (2016-2028)

FIGURE 024. INDUSTRIAL AUTOMATION MARKET OVERVIEW (2016-2028)

FIGURE 025. INDUSTRIAL IOT MARKET OVERVIEW (2016-2028)

FIGURE 026. INDUSTRY 4.0 MARKET OVERVIEW BY VERTICAL

FIGURE 027. MANUFACTURING MARKET OVERVIEW (2016-2028)

FIGURE 028. AEROSPACE AND DEFENSE MARKET OVERVIEW (2016-2028)

FIGURE 029. AUTOMOTIVE MARKET OVERVIEW (2016-2028)

FIGURE 030. OIL AND GAS MARKET OVERVIEW (2016-2028)

FIGURE 031. ENERGY & UTILITIES MARKET OVERVIEW (2016-2028)

FIGURE 032. ELECTRONICS AND CONSUMER GOODS MARKET OVERVIEW (2016-2028)

FIGURE 033. OTHERS MARKET OVERVIEW (2016-2028)

FIGURE 034. NORTH AMERICA INDUSTRY 4.0 MARKET OVERVIEW BY COUNTRY (2016-2028)

FIGURE 035. EUROPE INDUSTRY 4.0 MARKET OVERVIEW BY COUNTRY (2016-2028)

FIGURE 036. ASIA PACIFIC INDUSTRY 4.0 MARKET OVERVIEW BY COUNTRY (2016-2028)

FIGURE 037. MIDDLE EAST & AFRICA INDUSTRY 4.0 MARKET OVERVIEW BY COUNTRY (2016-2028)

FIGURE 038. SOUTH AMERICA INDUSTRY 4.0 MARKET OVERVIEW BY COUNTRY (2016-2028)

Frequently Asked Questions :

The forecast period in the Industry 4.0 Market research report is 2024-2032.

General Electric, ABB, Rockwell Automation, IBM, PTC, Honeywell, Johnson Controls International plc, Siemens, Bosch Rexroth, Schneider Electric, Fanuc Corporation, Toshiba Corporation, Yaskawa Electric Corporation, Mindray Medical International Limited, Haier Group Corporation, Huawei Technologies Co., Ltd., BYD Company Limited, Tata Consultancy Services (TCS), Infosys, Mahindra & Mahindra, Foxconn Technology Group, Samsung Electronics, Lenovo Group, ASE Technology Holding Co., Ltd., Hitachi, Ltd., Advantech Co., Ltd. and Other Major Players.

The Industry 4.0 Market is segmented into Technology, Application, Industry, and region. By Technology, the market is categorized into Industrial Robots, AI in Manufacturing, Digital Twin, Machine Vision, Industrial Sensors, Blockchain, Machine Condition Monitoring, Industrial 3D Printing, HMI, and AGVs. By Application, the market is categorized into Smart Factory, Industrial Automation, and Industrial IoT. By Industry, the market is categorized into Manufacturing, Aerospace and Defense, Automotive, Oil and Gas, Energy & Utilities, Electronics, and Consumer Goods, Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

Industry 4.0 marks a transformative era in the business landscape, reshaping how products are created, refined, and distributed. This paradigm shift involves the integration of cutting-edge technologies like the Internet of Things (IoT), cloud computing, artificial intelligence (AI), and machine learning into manufacturing processes.

Industry 4.0 Market Size Was Valued at USD 126.01 Billion in 2023, and is Projected to Reach USD 664.46 Billion by 2032, Growing at a CAGR of 20.29% From 2024-2032