Nitrogen Generator Market Synopsis

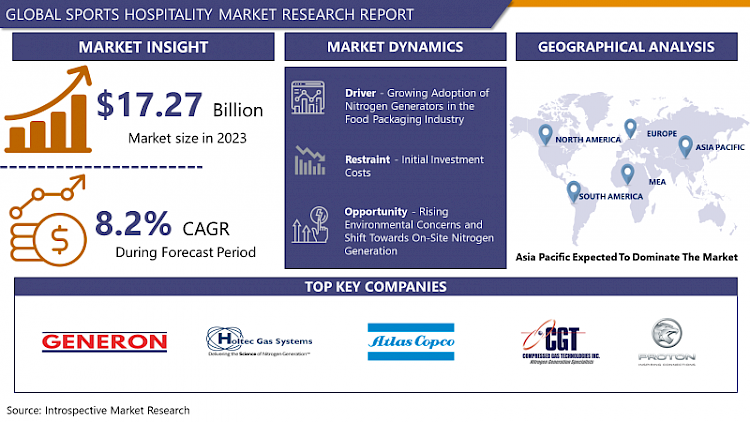

Nitrogen Generator Market Size Was Valued at USD 17.27 Billion in 2023, and is Projected to Reach USD 35.09 Billion by 2032, Growing at a CAGR of 8.20% From 2024-2032.

A nitrogen generator is a setup that is able to produce nitrogen gas form compressed air. It does the job via membrane separation, PSA (pressure stride adsorption) or cryogenic method which take away oxygen and other impurities from the air making it pure nitrogen. Which of these machines are employed in food packaging, electronics manufacturing, pharmaceuticals, chemical processing and so on, as a common source of nitrogen being a little pricey but at the same time reliable and cost-effective due to various applications.

- Nitrogen generators market space is getting its rapid growth in the recent years because of a demand for nitrogen in different sectors which include food and beverage, electronic industries, healthcare, and chemicals. Supplying nitrogen gas through nitrogen generators that utilize the process of air purification via technologies such as PSA or membrane system are valuable solutions, as they are available and less costly. The market growth is propelled by a number of fields.

- The emerging trend of nitrogen generators in the food and beverages industries, is the main forces that is pushing the industry. In the food, nitrogen gas finds wide application in the manufacture of various packaging methods that provide for an extended shelf life of perishable goods and prevent oxidation thus conserving quality and freshness. Furthermore, nitrogen is the gas used to keep wine and beer tasting great by maintaining their carbonation and freshness to satisfy customers in the breweries, wineries, and soft drinks industries that require nitrogen machines for their processes.

- Compared to air, nitrogen in electronics industry heavily utilized for its rarity kind of gas, the very rare type of gas that helps prevent the process of oxidation and after being used in electronic products like soldering, reflow soldering and wave soldering, nitrogen improves the quality and performance. Due to the electronic industry being going through the developments and accelerations in technology inevitably this brings a need for nitrogen generators to grow.

- Healthcare industry constitutes a very profitable segment within nitrogen generators, primarily in the case of medical gas applications such as nitrogen flushing and blanketing of medication which require keeping product stability and integrity. Besides nitrogen, the process employs its gas in the preservation of human tissues and cryosurgery as observed in biotech labs and clinics. The upcoming trends of healthcare infrastructure & development and improvement in the technology of medical science will only lead to the rapid increase in demand for nitrogen generators for use in the healthcare sector.

- Increased demand for nitrogen gas in industries which use it to cover, protect, and fill the facilities from fires and explosions and in order to ensure the perfect product qualities and purity. The development of industries that are closely bound with nitrogen, along with the safety regulations of hazardous substances transportation, will register a growth of nitrogen generators for industrial utilizations.

- innovations in nitrogen generation techniques ( design of the low-energy-consumption and low space-occupied systems) together with the widely of application of these techniques are additional factors that are pushing the market. Supply companies are hence concentrating on the effectiveness, efficiency, and expense efficiency of generating devices in order to meet requirements of final customers which are spread out among different industrial segments.

Nitrogen Generator Market Trend Analysis

Growing Adoption of Nitrogen Generators in Food Packaging Industry

- The ammonia generator market has experienced a lot of interest by the industry players, given that several key growth factors drive its growth with emphasis on the food packaging. Nitrogen generators are oftentimes deemed as a safe and inexpensive method for maintaining a controlled environment required to ensure the quality of perishable goods thus, extending their shelf life. Consequently,Consumers more and more shift preference to ready meals,generating challenge for manufactures to use nitrogen generators in order to maintain the quality and safety of the food they produce.

- One of the main reasons people switch to the use of the nitrogen generator is that these nitrogen generators replace oxygen from the air inside the packages. Through the utilization of nitrogen instead of oxygen in the manufactured systems, the aerobic microorganisms are prevented from their healthy development, including bacteria, mold, and yeast, which are the main source of foul smell and shorten the shelf life of the food. This nitrogen, as an inert gas, ensures that packaged items are kept fresher for an extended duration thus lowering the chances of spoilage and contamination and hence improving the entire quality of the products.

- Besides, nitrogen generators deliver unequal levels of flexibility and scalability which gives an opportunity to a great variety of food packaging industries, from snack food businesses to producers of fresh fruits and beverage producers. Whatever the possibility for the MAP (Modified Atmosphere Packaging) since it can extend the shelf life of perishable or nitrogen flushing in snacks packaging format , these systems can be customized in accordance with required needs and the packaging shape.

- In addition to the convincing financial case and the advantages already mentioned for optimum engine combustion in kitchen appliances, there is a growing trend towards sustainability and environmental awareness in the food industry which is also a driver in the adoption of nitrogen generators. On the contrary, with traditional food conservation such as chemical additives and excessive packages of materials, instead of nitrogen generators that offer a clean and eco-friendly approach. Manufacturers also take advantage of the local air to generate on-site nitrogen, which results in <u>a massive decrease in transport related carbon footprint because manufacturers do not have to carry nitrogen cylinders or stock up liquid nitrogen.

- Thanks to the recent breakthroughs in nitrogen generator technology, sustainability and efficiency have advantageously increased even more,speeding up their market expansion in the food packaging industry. The current nitrogen generators which are innovative, incorporate advanced automation features, remote monitoring capabilities, and in-built safety measures in them, thus making their integration into ongoing production very smooth and unrestricted.

Rising Environmental Concerns and Shift Towards On-Site Nitrogen Generation

- The growing call for environmental conservation and safeguarding of our planet has led to a visible trend towards on-site nitrogen production; this has resulted in the introduction of more nitrogen generators into the marketplace. Apart from the industries which require nitrogen usually have relied on delivered liquid nitrogen or cylinder nitrogen because these are dangerous for the environment since they contribute to carbon emissions and are also risky.

- While it might be an eco-friendly and cost-effective alternative to on-site nitrogen generation, it poses specific challenges in terms of infrastructure and scalability. Through application of techniques like PSA or membrane nitrogen generation, business have in place the production of nitrogen at the facilities by themselves from compressed air, hence making the transportation and thereby the carbon footprint needless.

- This transformation contributes to the worldwide sustainability efforts, since it reduces the dependence on fossil fuels and lowers the overall energy use as it relates to the extraction and usage of nitrogen.

- Moreover, on-site geneering leads to better regimes and the ability to optimize nitrogen rates, improving efficiency and reducing the risk of a shutdown. Due to the fact that the environmentally conscious public is growing, it is difficult to predict an increase in demand for an on site generator nitrogen and, as a result, this will be the catalyst that will speed up innovations aimed at increasing the share of the market for nitrogen generators which is expected to expand even further.

Nitrogen Generator Market Segment Analysis:

Nitrogen Generator Market is segmented based on Type and Application.

By Type, PSA segment is expected to dominate the market during the forecast period

- PSA (Pressure Swing Adsorption): Nitrogen gas generators based on the PSA technology employ a process known as molecular adsorption of air molecules of nitrogen. Employing such mechanism of passing compressed air through an adsorbent tank filled with molecular sieve material (e.g. activated carbon or zeolite), these devices capture the contaminants. Absorption of oxygen and other gases takes place on the surface of the sieve material, where nitrogen gas goes through and leaves behind for further utilization in non-flammable purposes.

- Membrane Nitrogen Generators: Membrane nitrogen generators make distrcongation nitrogen from other gases in the air by means of Si-permable membranes. Air is filtered so it is underpressure. As a result, many large gases, including oxygen, are unable to pass through the membrane more easily than nitrogen due to its different membrane permeability. AIMSUS perfectly illustrates this kind of process, as a result, a stream where nitrogen is enriched is produced, and it is collected as such.

- Cryogenic Air Separation: The process of cryogenic air separation is mainly about heat exchangers separation of nitrogen, from oxygen and other gases by using the differences in boiling points. The air under consideration, first, is cooled and then compressed where extracting the heat from the compressed air takes place, which is subsequently passed through a sequence of heat exchangers and distillation columns, where it is cooled at even lower temperatures. The lower temperatures are enough for component separation; the air liquifies at different points, which means that each component can be separated. Nitrogen is usually the gas in this process that is the first to be absorbed and then further enriched.

By Application, Food & Beverage segment held the largest share in 2023

- Electrical & Electronics: Nitrogen is employed for excluding, shrouding and packaging in the sales and electronics industry to block the oxidation or toation during the manufacturing and storing process.

- Food & Beverage: The applications of nitrogen in the food and beverage industry are extended to the food packaging to prolong the shelf life, enhance the product freshness and shield against spoilage by replacing the oxygen with nitrogen.

- Transportation: In many transportation functions, like in aeropace industry for example, nitrogen generators have become an indispensable tool. They are used as the tire inflators and fuel tank inerting agents, which contribute to the safety and performance of the aircraft.

- Chemical: Nitrogen is being used as a key chemical intermediary for many operations such as inerting, blanketing, and purging to rid unwanted oxidation, decreased efficiency, and dangerous reactions while chemical plants are running.

- Medical & Pharmaceuticals: The nitrogen is essential in the medication as well as in the pharmaceutical items for preserving the sensitive elements like drugs, vaccines, and biological samples as well as the nitrogen is required in the medical gas system for the surgery and the healing of the patient.

Nitrogen Generator Market Regional Insights:

Asia Pacific is Expected to Dominate the Market Over the Forecast period

- The Asia Pacific region‘ is expected perform exceptionally well and dominate the nitrogen generator market over the forecast period and there are few important factors, which are behind this.

- Firstly, the tipping point was set by the thriving industrial sector in the area which provided the realm for the production of nitrogen generators e.g. machinery, electronics, chemicals and health care. Polymer, petrochemicals, and steel are realms of these firms where they demand a nitrogen such as inerting, blanketing, purging to be fulfilled for product quality, safety, and operations streamlining.

- By the view of the future, as economies of Asia Pacific are expected to develop and industrialize, there will be an urgent need for nitrogen generators, which will be escalated.

- An additional push factor that has made it imperative to get these nitrogen generators into use in this area is the mounting pressure for sustainability and lowering costs.

- Nitrogen generators provide substantial benefits for the alternatives like cylinder delivery or liquid nitrogen tanks converting into the gaseous form that are commonly used They deliver a reliable and a nitrogen production alternative at customer location eliminating the costs and carbon footprint related to transportation, storage, and drumming of nitrogen cylinders or tanks.

- This is where theme of conserving the environment and cost effectiveness in nitrogen generator's deployment with which the region identifies very well..

- Notably, tech advancements and newty snomgens of the nitrogen creating devices are improving their throught, reliability, and adaptability, that is why more and more industries in this part of the globe are taking them into consideration.

- The front lines of these enhancements are made up of membrane technology which is a new generation process, pressure swing adsorption (PSA), and cryogenic distillation that allows nitrogen generators to meet all diverse application intentions and demands with high-impurity levels and low energy consumption.

- The governments of the Asian and Pacific countries implemented various programs and rules for the purpose of encouraging industrial progress, innovation, and sustainability and as a result, the nitrogen generator market attains a favourable atmosphere to grow in this region.

- Governments are giving out subsidies and other awards in order to provide recognition to those individuals who adopt energy-efficient and environmentally friendly technologies including nitrogen generators that are more intensively applied. Consequently, market growth is accelerated.

Active Key Players in the Nitrogen Generator Market

- IGS Generon(US)

- Holtec Gas Systems(US)

- Atlas Copco(Sweden)

- Compressed Gas Technologies(US)

- Parker Hannifin(US)

- Proton(India)

- NOXERIOR S.r.l.(Italy)

- SAM GAS Projects(India)

- Air Liquide(France)

- Other Key Players

Key Industry Developments in the Nitrogen Generator Market

- June 2023, PEAK has unveiled a series of exclusive technologies aimed at developing its most efficient nitrogen generator yet. Notable features comprise brushless compressors, which slash power consumption by more than 50%, a two-stage active moisture safeguard that significantly reduces the likelihood of moisture infiltration into the gas stream, and heat optimization technology, which shields the membrane from water droplets, thereby augmenting performance and reliability within the gas stream.

|

Global Nitrogen Generator Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 17.27 Bn. |

|

Forecast Period 2024-32 CAGR: |

8.20% |

Market Size in 2032: |

USD 35.09 Bn. |

|

Segments Covered: |

By Type |

|

|

|

By Application |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

- INTRODUCTION

- RESEARCH OBJECTIVES

- RESEARCH METHODOLOGY

- RESEARCH PROCESS

- SCOPE AND COVERAGE

- Market Definition

- Key Questions Answered

- MARKET SEGMENTATION

- EXECUTIVE SUMMARY

- MARKET OVERVIEW

- GROWTH OPPORTUNITIES BY SEGMENT

- MARKET LANDSCAPE

- PORTER’S FIVE FORCES ANALYSIS

- Bargaining Power Of Supplier

- Threat Of New Entrants

- Threat Of Substitutes

- Competitive Rivalry

- Bargaining Power Among Buyers

- INDUSTRY VALUE CHAIN ANALYSIS

- MARKET DYNAMICS

- Drivers

- Restraints

- Opportunities

- Challenges

- MARKET TREND ANALYSIS

- REGULATORY LANDSCAPE

- PESTLE ANALYSIS

- PRICE TREND ANALYSIS

- PATENT ANALYSIS

- TECHNOLOGY EVALUATION

- MARKET IMPACT OF THE RUSSIA-UKRAINE WAR

- Geopolitical Market Disruptions

- Supply Chain Disruptions

- Instability in Emerging Markets

- ECOSYSTEM

- PORTER’S FIVE FORCES ANALYSIS

- NITROGEN GENERATOR MARKET BY TYPE (2017-2032)

- NITROGEN GENERATOR MARKET SNAPSHOT AND GROWTH ENGINE

- MARKET OVERVIEW

- PSA

- Introduction And Market Overview

- Historic And Forecasted Market Size in Value (2017 – 2032F)

- Historic And Forecasted Market Size in Volume (2017 – 2032F)

- Key Market Trends, Growth Factors And Opportunities

- Geographic Segmentation Analysis

- MEMBRANE

- CRYOGENIC AIR

- NITROGEN GENERATOR MARKET BY APPLICATION (2017-2032)

- NITROGEN GENERATOR MARKET SNAPSHOT AND GROWTH ENGINE

- MARKET OVERVIEW

- ELECTRICAL & ELECTRONICS

- Introduction And Market Overview

- Historic And Forecasted Market Size in Value (2017 – 2032F)

- Historic And Forecasted Market Size in Volume (2017 – 2032F)

- Key Market Trends, Growth Factors And Opportunities

- Geographic Segmentation Analysis

- FOOD & BEVERAGE

- TRANSPORTATION

- CHEMICAL

- MEDICAL & PHARMACEUTICALS

- COMPANY PROFILES AND COMPETITIVE ANALYSIS

- COMPETITIVE LANDSCAPE

- Competitive Positioning

- Nitrogen Generator Market Share By Manufacturer (2023)

- Industry BCG Matrix

- Heat Map Analysis

- Mergers & Acquisitions

- IGS GENERON(US)

- Company Overview

- Key Executives

- Company Snapshot

- Role of the Company in the Market

- Sustainability and Social Responsibility

- Operating Business Segments

- Product Portfolio

- Business Performance (Production Volume, Sales Volume, Sales Margin, Production Capacity, Capacity Utilization Rate)

- Key Strategic Moves And Recent Developments

- SWOT Analysis

- HOLTEC GAS SYSTEMS(US)

- ATLAS COPCO(SWEDEN)

- COMPRESSED GAS TECHNOLOGIES(US)

- PARKER HANNIFIN(US)

- PROTON(INDIA)

- NOXERIOR S.R.L.(ITALY)

- SAM GAS PROJECTS(INDIA)

- AIR LIQUIDE(FRANCE)

- COMPETITIVE LANDSCAPE

- GLOBAL NITROGEN GENERATOR MARKET BY REGION

- OVERVIEW

- NORTH AMERICA

- Key Market Trends, Growth Factors And Opportunities

- Key Manufacturers

- Historic And Forecasted Market Size By Type

- Historic And Forecasted Market Size By Application

- Historic And Forecasted Market Size By Country

- USA

- Canada

- Mexico

- EASTERN EUROPE

- Key Market Trends, Growth Factors And Opportunities

- Key Manufacturers

- Historic And Forecasted Market Size By Segments

- Historic And Forecasted Market Size By Country

- Russia

- Bulgaria

- The Czech Republic

- Hungary

- Poland

- Romania

- Rest Of Eastern Europe

- WESTERN EUROPE

- Key Market Trends, Growth Factors And Opportunities

- Key Manufacturers

- Historic And Forecasted Market Size By Segments

- Historic And Forecasted Market Size By Country

- Germany

- United Kingdom

- France

- The Netherlands

- Italy

- Spain

- Rest Of Western Europe

- ASIA PACIFIC

- Key Market Trends, Growth Factors And Opportunities

- Key Manufacturers

- Historic And Forecasted Market Size By Segments

- Historic And Forecasted Market Size By Country

- China

- India

- Japan

- South Korea

- Malaysia

- Thailand

- Vietnam

- The Philippines

- Australia

- New-Zealand

- Rest Of APAC

- MIDDLE EAST & AFRICA

- Key Market Trends, Growth Factors And Opportunities

- Key Manufacturers

- Historic And Forecasted Market Size By Segments

- Historic And Forecasted Market Size By Country

- Turkey

- Bahrain

- Kuwait

- Saudi Arabia

- Qatar

- UAE

- Israel

- South Africa

- SOUTH AMERICA

- Key Market Trends, Growth Factors And Opportunities

- Key Manufacturers

- Historic And Forecasted Market Size By Segments

- Historic And Forecasted Market Size By Country

- Brazil

- Argentina

- Rest of South America

- INVESTMENT ANALYSIS

- ANALYST VIEWPOINT AND CONCLUSION

- Recommendations and Concluding Analysis

- Potential Market Strategies

|

Global Nitrogen Generator Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 17.27 Bn. |

|

Forecast Period 2024-32 CAGR: |

8.20% |

Market Size in 2032: |

USD 35.09 Bn. |

|

Segments Covered: |

By Type |

|

|

|

By Application |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

LIST OF TABLES

TABLE 001. EXECUTIVE SUMMARY

TABLE 002. NITROGEN GENERATOR MARKET BARGAINING POWER OF SUPPLIERS

TABLE 003. NITROGEN GENERATOR MARKET BARGAINING POWER OF CUSTOMERS

TABLE 004. NITROGEN GENERATOR MARKET COMPETITIVE RIVALRY

TABLE 005. NITROGEN GENERATOR MARKET THREAT OF NEW ENTRANTS

TABLE 006. NITROGEN GENERATOR MARKET THREAT OF SUBSTITUTES

TABLE 007. NITROGEN GENERATOR MARKET BY TYPE

TABLE 008. PSA MARKET OVERVIEW (2016-2028)

TABLE 009. MEMBRANE MARKET OVERVIEW (2016-2028)

TABLE 010. CRYOGENIC AIR MARKET OVERVIEW (2016-2028)

TABLE 011. NITROGEN GENERATOR MARKET BY APPLICATION

TABLE 012. ELECTRICAL & ELECTRONICS MARKET OVERVIEW (2016-2028)

TABLE 013. FOOD & BEVERAGE MARKET OVERVIEW (2016-2028)

TABLE 014. TRANSPORTATION MARKET OVERVIEW (2016-2028)

TABLE 015. CHEMICAL MARKET OVERVIEW (2016-2028)

TABLE 016. MEDICAL & PHARMACEUTICALS MARKET OVERVIEW (2016-2028)

TABLE 017. NORTH AMERICA NITROGEN GENERATOR MARKET, BY TYPE (2016-2028)

TABLE 018. NORTH AMERICA NITROGEN GENERATOR MARKET, BY APPLICATION (2016-2028)

TABLE 019. N NITROGEN GENERATOR MARKET, BY COUNTRY (2016-2028)

TABLE 020. EUROPE NITROGEN GENERATOR MARKET, BY TYPE (2016-2028)

TABLE 021. EUROPE NITROGEN GENERATOR MARKET, BY APPLICATION (2016-2028)

TABLE 022. NITROGEN GENERATOR MARKET, BY COUNTRY (2016-2028)

TABLE 023. ASIA PACIFIC NITROGEN GENERATOR MARKET, BY TYPE (2016-2028)

TABLE 024. ASIA PACIFIC NITROGEN GENERATOR MARKET, BY APPLICATION (2016-2028)

TABLE 025. NITROGEN GENERATOR MARKET, BY COUNTRY (2016-2028)

TABLE 026. MIDDLE EAST & AFRICA NITROGEN GENERATOR MARKET, BY TYPE (2016-2028)

TABLE 027. MIDDLE EAST & AFRICA NITROGEN GENERATOR MARKET, BY APPLICATION (2016-2028)

TABLE 028. NITROGEN GENERATOR MARKET, BY COUNTRY (2016-2028)

TABLE 029. SOUTH AMERICA NITROGEN GENERATOR MARKET, BY TYPE (2016-2028)

TABLE 030. SOUTH AMERICA NITROGEN GENERATOR MARKET, BY APPLICATION (2016-2028)

TABLE 031. NITROGEN GENERATOR MARKET, BY COUNTRY (2016-2028)

TABLE 032. IGS GENERON: SNAPSHOT

TABLE 033. IGS GENERON: BUSINESS PERFORMANCE

TABLE 034. IGS GENERON: PRODUCT PORTFOLIO

TABLE 035. IGS GENERON: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 035. HOLTEC GAS SYSTEMS: SNAPSHOT

TABLE 036. HOLTEC GAS SYSTEMS: BUSINESS PERFORMANCE

TABLE 037. HOLTEC GAS SYSTEMS: PRODUCT PORTFOLIO

TABLE 038. HOLTEC GAS SYSTEMS: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 038. ATLAS COPCO: SNAPSHOT

TABLE 039. ATLAS COPCO: BUSINESS PERFORMANCE

TABLE 040. ATLAS COPCO: PRODUCT PORTFOLIO

TABLE 041. ATLAS COPCO: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 041. COMPRESSED GAS TECHNOLOGIES: SNAPSHOT

TABLE 042. COMPRESSED GAS TECHNOLOGIES: BUSINESS PERFORMANCE

TABLE 043. COMPRESSED GAS TECHNOLOGIES: PRODUCT PORTFOLIO

TABLE 044. COMPRESSED GAS TECHNOLOGIES: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 044. LINDE ENGINEERING: SNAPSHOT

TABLE 045. LINDE ENGINEERING: BUSINESS PERFORMANCE

TABLE 046. LINDE ENGINEERING: PRODUCT PORTFOLIO

TABLE 047. LINDE ENGINEERING: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 047. ON SITE GAS SYSTEMS: SNAPSHOT

TABLE 048. ON SITE GAS SYSTEMS: BUSINESS PERFORMANCE

TABLE 049. ON SITE GAS SYSTEMS: PRODUCT PORTFOLIO

TABLE 050. ON SITE GAS SYSTEMS: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 050. PARKER HANNIFIN: SNAPSHOT

TABLE 051. PARKER HANNIFIN: BUSINESS PERFORMANCE

TABLE 052. PARKER HANNIFIN: PRODUCT PORTFOLIO

TABLE 053. PARKER HANNIFIN: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 053. SOUTH-TEK SYSTEMS: SNAPSHOT

TABLE 054. SOUTH-TEK SYSTEMS: BUSINESS PERFORMANCE

TABLE 055. SOUTH-TEK SYSTEMS: PRODUCT PORTFOLIO

TABLE 056. SOUTH-TEK SYSTEMS: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 056. PROTON: SNAPSHOT

TABLE 057. PROTON: BUSINESS PERFORMANCE

TABLE 058. PROTON: PRODUCT PORTFOLIO

TABLE 059. PROTON: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 059. NOXERIOR S.R.L.: SNAPSHOT

TABLE 060. NOXERIOR S.R.L.: BUSINESS PERFORMANCE

TABLE 061. NOXERIOR S.R.L.: PRODUCT PORTFOLIO

TABLE 062. NOXERIOR S.R.L.: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 062. PCI-INTL: SNAPSHOT

TABLE 063. PCI-INTL: BUSINESS PERFORMANCE

TABLE 064. PCI-INTL: PRODUCT PORTFOLIO

TABLE 065. PCI-INTL: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 065. SAM GAS PROJECTS: SNAPSHOT

TABLE 066. SAM GAS PROJECTS: BUSINESS PERFORMANCE

TABLE 067. SAM GAS PROJECTS: PRODUCT PORTFOLIO

TABLE 068. SAM GAS PROJECTS: KEY STRATEGIC MOVES AND DEVELOPMENTS

TABLE 068. AIR LIQUIDE: SNAPSHOT

TABLE 069. AIR LIQUIDE: BUSINESS PERFORMANCE

TABLE 070. AIR LIQUIDE: PRODUCT PORTFOLIO

TABLE 071. AIR LIQUIDE: KEY STRATEGIC MOVES AND DEVELOPMENTS

LIST OF FIGURES

FIGURE 001. YEARS CONSIDERED FOR ANALYSIS

FIGURE 002. SCOPE OF THE STUDY

FIGURE 003. NITROGEN GENERATOR MARKET OVERVIEW BY REGIONS

FIGURE 004. PORTER'S FIVE FORCES ANALYSIS

FIGURE 005. BARGAINING POWER OF SUPPLIERS

FIGURE 006. COMPETITIVE RIVALRYFIGURE 007. THREAT OF NEW ENTRANTS

FIGURE 008. THREAT OF SUBSTITUTES

FIGURE 009. VALUE CHAIN ANALYSIS

FIGURE 010. PESTLE ANALYSIS

FIGURE 011. NITROGEN GENERATOR MARKET OVERVIEW BY TYPE

FIGURE 012. PSA MARKET OVERVIEW (2016-2028)

FIGURE 013. MEMBRANE MARKET OVERVIEW (2016-2028)

FIGURE 014. CRYOGENIC AIR MARKET OVERVIEW (2016-2028)

FIGURE 015. NITROGEN GENERATOR MARKET OVERVIEW BY APPLICATION

FIGURE 016. ELECTRICAL & ELECTRONICS MARKET OVERVIEW (2016-2028)

FIGURE 017. FOOD & BEVERAGE MARKET OVERVIEW (2016-2028)

FIGURE 018. TRANSPORTATION MARKET OVERVIEW (2016-2028)

FIGURE 019. CHEMICAL MARKET OVERVIEW (2016-2028)

FIGURE 020. MEDICAL & PHARMACEUTICALS MARKET OVERVIEW (2016-2028)

FIGURE 021. NORTH AMERICA NITROGEN GENERATOR MARKET OVERVIEW BY COUNTRY (2016-2028)

FIGURE 022. EUROPE NITROGEN GENERATOR MARKET OVERVIEW BY COUNTRY (2016-2028)

FIGURE 023. ASIA PACIFIC NITROGEN GENERATOR MARKET OVERVIEW BY COUNTRY (2016-2028)

FIGURE 024. MIDDLE EAST & AFRICA NITROGEN GENERATOR MARKET OVERVIEW BY COUNTRY (2016-2028)

FIGURE 025. SOUTH AMERICA NITROGEN GENERATOR MARKET OVERVIEW BY COUNTRY (2016-2028)

Frequently Asked Questions :

The forecast period in the Nitrogen Generator Market research report is 2024-2032.

IGS Generon(US), Holtec Gas Systems(US), Atlas Copco(Sweden), Compressed Gas Technologies(US), Parker Hannifin(US), Proton(India), NOXERIOR S.r.l.(Italy), SAM GAS Projects(India),and Other Major Players.

The Nitrogen Generator Market is segmented into Type, Application and Region. By Product Type, the market is categorized into PSA, Membrane, Cryogenic Air. By Application, the market is categorized into Electrical & Electronics, Food & Beverage, Transportation, Chemical, Medical & Pharmaceuticals. By region, it is analyzed across North America (U.S.; Canada; Mexico), Europe (Germany; U.K.; France; Italy; Russia; Spain, etc.), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

A nitrogen generator is a device that produces nitrogen gas from compressed air. It utilizes various technologies such as membrane separation, pressure swing adsorption (PSA), or cryogenic separation to remove oxygen and other impurities from the air, leaving behind a high-purity nitrogen stream. These generators are used in a wide range of industries, including food packaging, electronics manufacturing, pharmaceuticals, and chemical processing, where a reliable and cost-effective source of nitrogen is required for various applications.

Nitrogen Generator Market Size Was Valued at USD 17.27 Billion in 2023, and is Projected to Reach USD 35.09 Billion by 2032, Growing at a CAGR of 8.20% From 2024-2032.